As is known, the structure and properties of mineral wool during the operation of a thermal insulation structure can change significantly as a result of self-sealing, especially during vibration and humidification. The consequence of these factors is the inconstancy of the volume of the thermal insulation structure, instability during vibration and low mechanical strength.

The efficiency of thermal insulation is guaranteed by a more advanced design and competent installation.

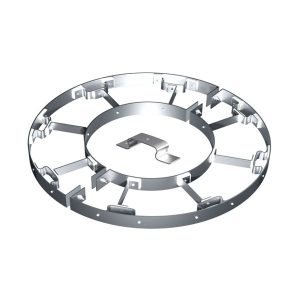

To preserve and improve the efficiency of the thermal insulation characteristics of thermal insulation at a given level, various metal frames are installed, on which protective coatings are mounted:

● for pipelines with a nominal diameter of less than 100 mm – support brackets;

● for pipelines with a nominal diameter of more than 100 mm – support distance rings on metal racks.

To solve this problem, special support and unloading structures have been developed, produced on automatic European CNC lines.