Home page » Range of services PIPEWOOL

Range of services PIPEWOOL

Installation of thermal insulation, shells and structures for various purposes

Our company employs specialists with extensive experience who will help you make the right choice based on your needs.

Development and production of non-standard designs for thermal insulation

Our production facilities are equipped with the necessary equipment and specialists to perform various non-standard solutions

Taking measurements from pipes or thermal insulation

Our specialists are ready to provide you with information support for the removal of the exact dimensions from the insulated structure or to carry out a visit to the object and make measurements on their own, having previously signed a service agreement.

Cutting and cutting of blanks into shaped products

The use of CNC-controlled machines at the pre-production stage allows you to obtain high-precision standard sizes of product blanks and guaranteed quality in the end.

Technical Insulation Calculation Calculator

From thermal insulation material to protective shells You do not need to look for a manufacturer for your project

Calculation of insulation thickness

Thermal insulation products and Protective shells of TM PIPEWOOL in the program "Insulation" - "NTP Pipeline" The program is used to calculate thermal insulation and issue design documents using products

Longitudinal and transverse metal cutting

Cut sheet metal from rolls into strips/tape, sheets/cards of a given size, allowing you to optimize your production time and waste.

Production of drainage systems

Ready-made solutions for drainage systems in a wide range Metal gutters made of galvanized steel with a polymer coating serve for decades and add charm to the architectural ensemble of the building

Insulation of structures by blowing machine

Insulation of building structures with the help of bulk / blown cotton wool is an effective method of thermal insulation of attics, floors, coverings, floors and walls

Installation of thermal insulation, shells and structures for various purposes

One of the main activities of our company is the production of thermal insulation materials and thin-sheet shells (okozhushka) to protect the thermal insulation of pipelines, equipment and air ducts.

We offer you a full range of services in thermal insulation and sound insulation, manufacturing, delivery and installation: thermal insulation, substructures, okozhushivaniyu metal shells to protect the thermal insulation layer.

With modern equipment, tools and highly qualified personnel, we quickly fulfill orders of any technical complexity with constant quality, which allows us to meet the highest requirements of professionals, as well as customers who purchase our products for one-time work.

In an effort to make cooperation as profitable as possible for our partners, it is possible for a specialist to visit the site for advice and assistance in determining the size of the shells, as well as providing installation supervision services.

MANUFACTURE AND INSTALLATION OF SOUND INSULATION

Sound insulation is regulated by regulatory requirements.

We are ready to produce for you individual sound-proof structures and boxes for compressor, blower and pumping equipment.

Complete solutions for industrial heating

To prevent icing/thawing of industrial installations, we offer individual technical solutions with the calculation of the electric heating system, the selection of thermal insulation material and the manufacture of protective coatings.

We are always ready to provide you with information support for the calculation of non-standard designs and together with you to take part in the search for a unique solution. And also, we are ready to offer a ready-made solution from our side. We are ready to carry out a visit to the object and conduct measurements on our own, having previously signed a service agreement.

DEVELOPMENT AND PRODUCTION OF NON-STANDARD DESIGNS FOR THERMAL INSULATION

Non-standard designs, according to the generally accepted terminology, are such products of complex design, which are most often made in one copy and are, in essence, unique. Or the standard sizes and configuration of the structure do not fit into the standards of the usual standard sizes of products.

Such structures are made according to sketches or drawings using non-standard solutions that are dictated by the production need for a particular node or connection. In fact, they fully comply with all accepted standards, GOST, SNIP and safety regulations.

Our production is equipped with the necessary equipment and specialists to perform such non-standard solutions, we are ready to take on a full range of work on the production of such non-standard structures.

The need for this type of product arises when there is a task that requires a unique solution. A typical situation in production is either expansion or modernization of the technological process. In the case of any emergency situations, there is also sometimes a vital need for non-standard approaches and the use of unique structures.

Another typical problem during modernization is the need to replace certain types of structures, the production of which is either completely discontinued or not mass-produced. And our company’s specialists, who have considerable production experience, will help you to cope with this task.

Taking measurements from pipes or thermal insulation

Our specialists are ready to provide you with information support for the removal of the exact dimensions from the insulated structure or to carry out a visit to the object and carry out measurements on their own, having previously signed a service agreement.

Taking measurements from pipes or thermal insulation

For high-quality installation of thermal insulation and protective layers, it is necessary to ensure a tight fit of the coatings to the insulated surface.

The technology of performing a metal coating of thermal insulation consists of determining the size of metal workpieces, their manufacture and installation in place.

Removing the outer dimensions of the insulation allows you to determine the exact dimensions of the coating of the protective shells. According to the obtained measurements (taking into account overlaps), a complete list is compiled, which shows the dimensions and number of required blanks and elements for coating. This document is sent to the workshop and serves as an application.

The production of metal coatings is carried out according to the data of full-scale measurements of the insulation surface.

If you do not have sufficient experience and qualifications, our specialists are ready to provide you with information support to carry out the removal of the exact dimensions of the insulated structure or to carry out a visit to the object and make measurements on their own, having previously signed a service agreement.

The use of CNC-controlled machines at the pre-production stage allows you to obtain high-precision standard sizes of product blanks and guaranteed quality in the end. We are always ready to provide you with information support and advice on various issues that require mutual attention for their effective and positive solution.

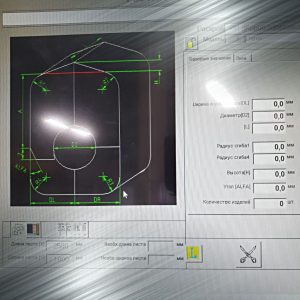

CUTTING AND CUTTING OF BLANKS INTO SHAPED PRODUCTS

The range of shaped products is very wide and includes many elements, including those with complex configurations, for the manufacture of which it is required to produce sections of various contours, shapes and configurations.

The process of cutting any material involves a number of manipulations, such as pressing, punching, cutting, cutting, cutting, trimming. The purpose of these procedures is the production of various parts and blanks. Cutting is carried out on high-tech CNC machines by influencing the material of different types of tools, depending on the task and the desired result in the end.

The use of CNC-controlled machines at the pre-production stage is one of the most urgent tasks of modern machine-building production. With the help of the CNC, currently, a large number of tasks are solved. Such as the choice of the type of workpiece, its purpose, manufacturing method, calculation of processing allowances, optimization of the production process during manufacturing, temperature tolerances. And also, when designing the manufacturing technology and manufacturing processes, which is a rational disclosure of a particular type of material used, taking into account all the necessary requirements, technical specifications, SNIPS and GOST standards.

Longitudinal and transverse metal cutting

* To avoid mechanical damage, the finished products are placed on pallets and tied together with a tape.

In our arsenal there are 4 lines of longitudinal and transverse cutting of sheet metal with the following indicators:

● Profiilikeskus line (Finland), width 1,250 mm / thickness 1,25 mm. Includes 2 functions (transverse and longitudinal cutting) produced on the same equipment.

● Almore line (France), width 1000 mm / thickness 1.0 mm. It includes 4 functions (transverse and longitudinal cutting, knurling of stiffeners, punching holes).

● Mabi line (Switzerland), width 1000 mm / thickness 1.0 mm. It includes 3 functions (cross-cutting, knurling of stiffeners, punching holes).

● Mabi line (Switzerland), width 1250 mm / thickness 1.2 mm. It includes 3 functions (cross-cutting, curved cutting, including programs for cutting blanks of elements for ventilation and insulation, punching holes).

OUR ADVANTAGES:

● Own high-quality equipment;

● The ability to quickly switch from one cutting card to another;

● Types of processed metal: cold rolled, galvanized, stainless, aluminum;

● Production of any order within up to 3 days;

● The possibility of unwinding the customer’s metal.

Areas of application of longitudinal and transverse cutting:

● Production of metal advertising stands;

● The installation of the roof;

● Installation of ventilation and heating systems;

● Production of stamping products;

● Construction of industrial structures made of metal and much more.

Water is the source of life and the reason for the beginning of the earlier destruction of facade materials and load-bearing walls. Drainage systems are essential and integral elements of any building for the controlled drainage of precipitation and the protection of buildings. These systems are so firmly embedded in our lives that they have long been decorative elements of buildings, and sometimes an integral part of their architectural ensemble as a whole.

PRODUCTION OF DRAINAGE SYSTEMS

An important component of any building is a drainage system, which includes a large list of various elements connected to each other and designed to divert rain and meltwater from the structure/building. Production of drains should be carried out professionally and taking into account those defects that can negatively affect the quality of the entire system as a whole.

Important functions performed by drainage systems:

● Significantly reduce the risk of flooding in basements and basements;

● Reduce indoor humidity in the building. As we know, humidity contributes to the undesirable appearance of mold and dampness, and when using drainage systems, it is reduced to zero;

● Protect the facade of the building by diverting water from the structure, and the foundation and plinth from irreparable damage;

● Gutters and elements of gutters can be used as a decorative decoration of the building, which gives it an additional attraction and a finished look;

● In the adjacent areas to the structure becomes clean and dry, less dirt and puddles are formed, which adds an even greater plus to the structure’s aesthetics.

The production of each element of the drain is carried out individually, in accordance with the characteristics of the building and the surrounding area.

PIPEWOOL produces high-quality drainage systems at affordable prices.

Our experienced staff will be sure to advise you on all your questions and provide you with comprehensive and useful information necessary when choosing the material and design of water drains.

It is used for insulation of attics, ceiling space and floor: when insulating the attic space, the entire horizontal surface of the attic is covered with an even layer of cotton wool, which also envelops the ventilation pipes, filling the smallest gaps. Relative to the brickwork, a layer of blown cotton wool in 20 cm is equal to 2.5 bricks.

INSULATION OF STRUCTURES BY BLOWING MACHINE

Insulation of building structures with the help of bulk / blown wool is an effective method of thermal insulation of attics, floors, coverings, floors and walls. By purchasing bulk thermal insulation, you save 40-70% of your money compared to the purchase of any other thermal insulation. Bulk / blown thermal insulation has absolute fire safety, the mineral fibers of the material are able to withstand high temperatures. The flowability of the material allows you to fill hard-to-reach voids, places, and cracks. When leveling the surface, there are no cold bridges at all.

Characteristics of bulk / blown cotton wool:

● It is a non-combustible material (flammability group NG);

● Long decomposition period (50 years);

● Chemical resistance;

● Thermal conductivity (0.036 W/(m – °C));

● Water absorption (no more than 2 %);

● density 35-60 kg / cubic meter (can easily be mechanically compacted to 60 kg/cubic meter, further compaction will increase the thermal conductivity coefficient).