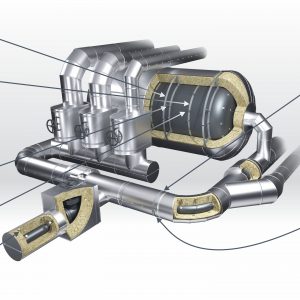

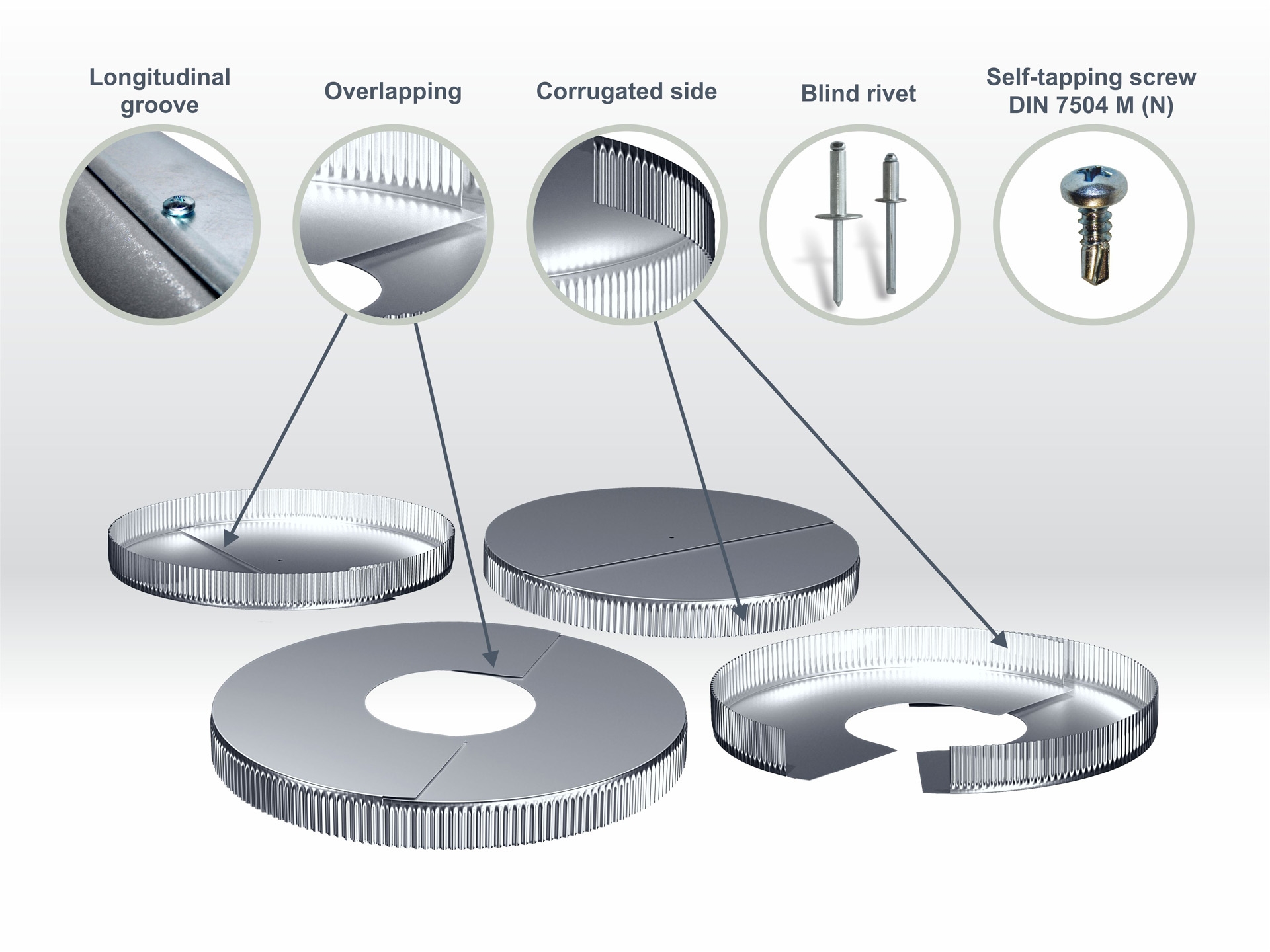

The protective shell on the diaphragm “Pipewool GdZn/GdAl/GdSt” is a modern solution for protecting thermal insulation and pipeline networks from external influences. It is a protective coating made of thin-sheet steel. Special stiffeners, technological locks allow you to prevent moisture from entering the casing.

The protective shell on the plug or diaphragm serves as protection on the final section of the pipeline. And also, the diaphragm is part of the unloading device to prevent vertical displacement (sliding) of protective coatings on vertical pipelines and apparatuses when using soft thermal insulation materials. Type of metal made of galvanized steel, stainless steel and aluminum sheets up to 0.50 – 1.0 mm thick.

Types of execution of the plug or diaphragm: one-piece and prefabricated (from 2 to 4 elements), flat and with a rim, with a hole of the diameter required by the customer.