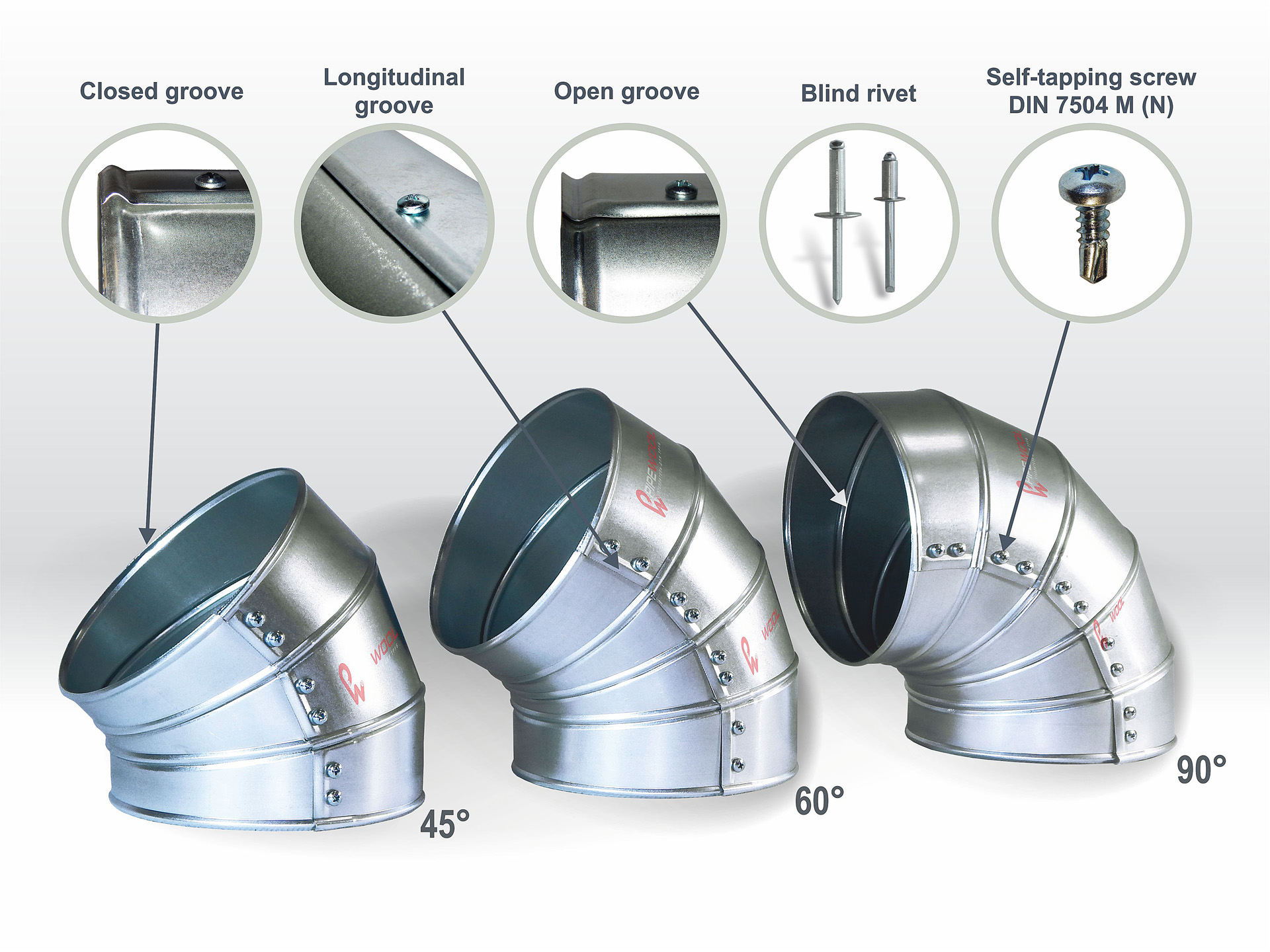

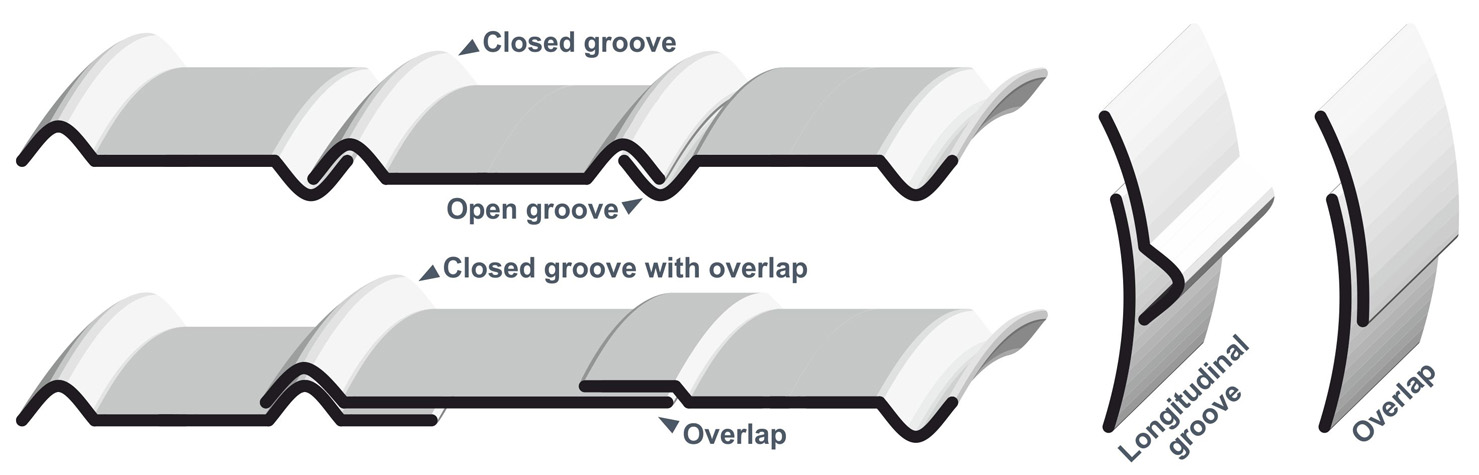

Pipewool O Zn/Al/St protective shell is a modern solution for protecting thermal insulation and pipeline networks from external influences. It is a protective coating made of thin-sheet steel. Special stiffeners, longitudinal and end overlays, technological locks allow you to prevent moisture from entering the casing.

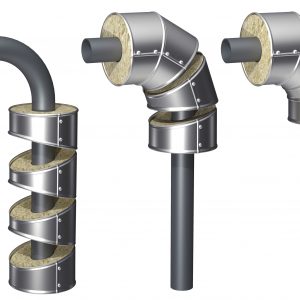

Truncated or beveled elbows-used in hard-to-reach or cramped conditions of dehumidification, as a rule, these are the intersections of branches with the pipeline and any building structures and equipment. Any segment or several segments on any side can be truncated, as well as with alternating segments and sides.

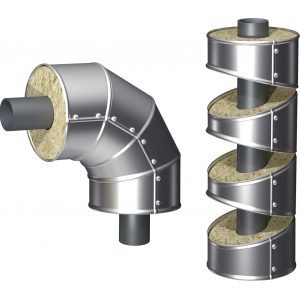

Elbows of the transition section-used in places of rotation, where the technological transition of the pipe from one section to another is necessary.

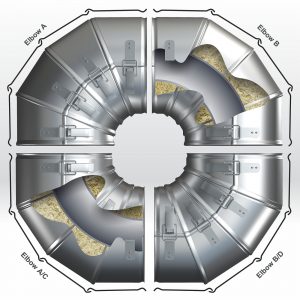

Double vertical and horizontal elbows-used in cramped conditions, in which the pipes in the places of rotation are located too close to each other and the installation of the protective shell must be made entirely on two pipes.