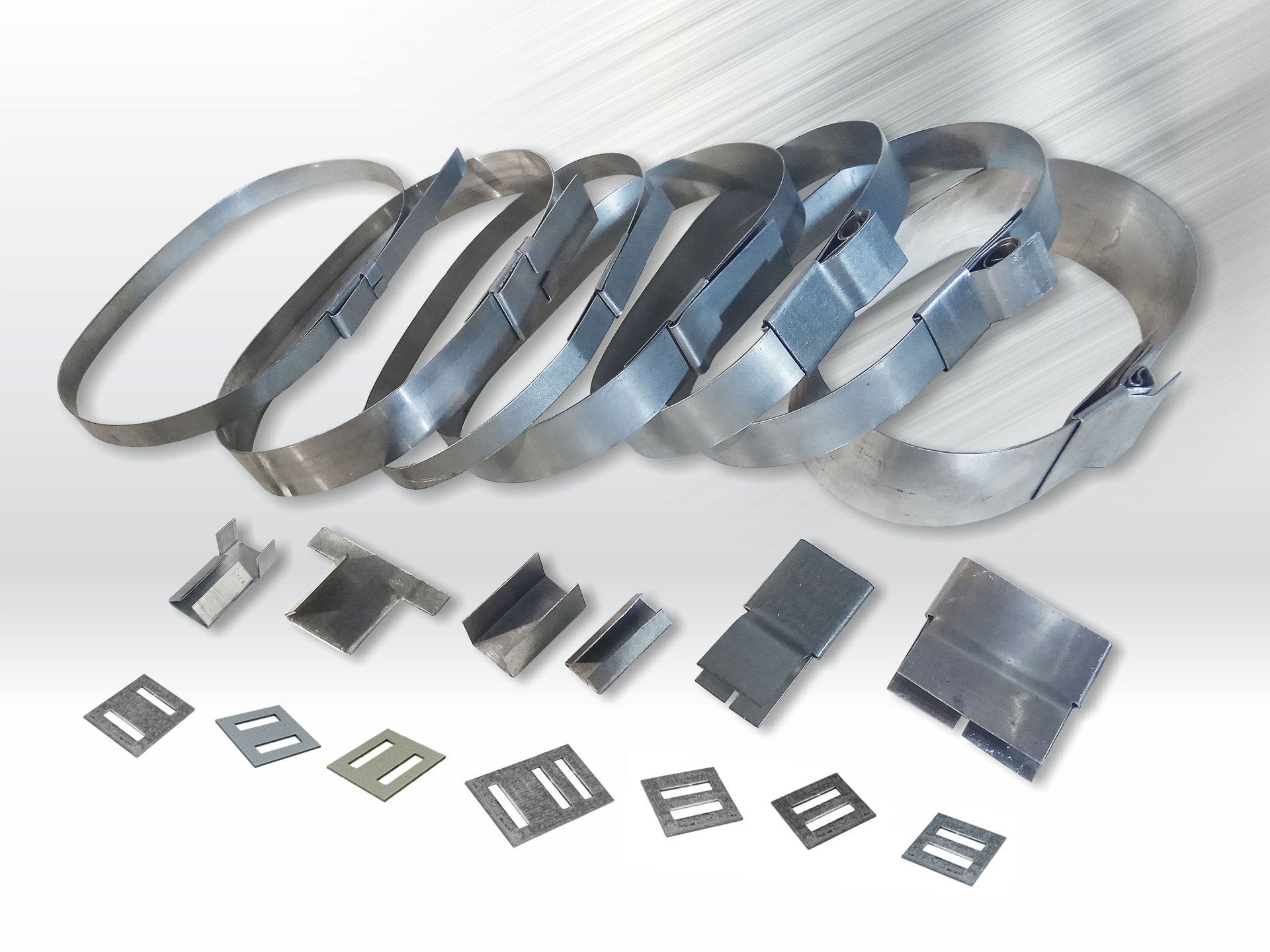

Binding buckles are designed for connecting metal bandages of thermal insulation of industrial facilities, buildings and structures. Buckles, depending on the design, are divided into the following types: I, II, III, IV.

The designation of the buckle type should include a symbol indicating the type of metal from which the buckle should be made, namely: A-aluminum alloy or aluminum, O-galvanized steel, C-thin-sheet roofing steel.

The type of metal from which the buckle should be made must correspond to the thermal insulation project developed by a specialized organization.

Type of climatic design made of thin-sheet roofing steel (C) – YI according to GOST 15150-69.

Examples of buckle designations when ordering:

Buckle type I-А TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type I-О TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type I-С TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type II-А TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type II-О TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type II-С TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type III-А TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type III-О TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type III-С TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type IV-А TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type IV-О TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type IV-С TECHNICAL CONDITIONS 36.16.22-64-92;

Buckle type 2SL-O (double-slit buckle);

Characteristics (properties):

• Aluminum or aluminum alloy (A) according to GOST 21631-76 (grades ADI, AMc, AMg). According to the state of delivery, the sheets must be semi-nagartovannye or nagartovannye;

• Thin-sheet galvanized steel (O) according to GOST 14918-80 (grade according to GOST 19904-90);

• Hot-rolled thin-sheet rental according to TECHNICAL CONDITIONS 14-11-252-89 (grade according to GOST 19903-74), cold-rolled thin-sheet roofing (C) rental according to TECHNICAL CONDITIONS 14-11-262-89 (grade according to GOST 19904-90).

• It is allowed to produce a buckle from the corresponding metal according to other standards, subject to

the consent of the customer.

• Buckles made of rolled thin-sheet roofing must have a paint and varnish coating of class II according to GOST 9.032-74, a group of operating conditions of a product with a coating of class I according to GOST 9.104-79.

• Preparation of metal surfaces before painting, coating should be carried out in accordance with the requirements of GOST 9.402-80.

• The average service life of the buckle before its replacement should be at least 5 years.

• Completeness: buckles (of the same type in one box); label (one per packing box), made in accordance with GOST 2.601-68.

Marking:

• Transport marking in accordance with the requirements of GOST 14192-77 must be applied to each cargo place (box with buckles) with indelible paint.

Packaging:

• The buckles are delivered to the consumer in a packed form. The packaging must comply with the category KU-I according to GOST 23170-78.

• Before packing, buckles made of aluminum or its alloys, as well as galvanized steel buckles, at the request of the customer, must be preserved in accordance with the requirements of GOST 9.014-78 for group I-I for storage and transportation conditions 5 (OZH4) according to GOST 15150-69. The protection period without re-preservation is 12 months. In the absence of customer requirements, the buckles are delivered without preservation.

• Buckles sent to the consumer must be placed in board boxes of type II-2 according to GOST 2991-85.

• The net weight of the cargo space (box) should not exceed 55 kg. The dimensions of the cargo space must comply with GOST 21140-75.

• Before packing the buckles, the boxes must be lined inside with waterproof packaging paper of the DB brand according to GOST 8828-89 or packaging paper according to GOST 515-77.

• A packing list must be enclosed in each box, which indicates:

1) the name or trademark of the manufacturer;

2) name and total number of buckles;

3) the name or number of the packer;

4) the date of packaging.

• It is allowed not to put the packing list in the box if the information to be stated in the packing list will be given by the manufacturer in the label.

• The label and packing list are packed in a bag made of plastic film GOST 10354-82 or polyvinyl chloride plasticized technical film GOST 16272-79 or other waterproof material that is fixed in the box.

Installation conditions:

When using clamps with a buckle, it is necessary to control the tightness of the insulation layer to the pipeline and the accuracy of the coupling of the elements of the insulation layer, as well as the metal coating.

A necessary condition for installation-the work should be carried out in dry weather to avoid precipitation in the form of moisture or condensate on the surface of the insulation.