Home page » Products » Protective shell for Ventilation » Tees-ТY ventilation PIPEWOOL

Tees-ТY ventilation PIPEWOOL

TECHNICAL CONDITIONS 23.99.19-006-61278130-2019

Ventilation is used to create an exchange of air masses inside the room with the environment in order to remove fumes, unpleasant odors, pollutants, carbon dioxide and carbon monoxide, etc. from the room. If simple natural ventilation is sufficient for small rooms, then for extensive complexes with many separate rooms, the ventilation system can be very complex and branched, with numerous branches, transitions, tees, etc. For high-quality ventilation work, it is necessary to have a competent calculation, high-quality installation, appropriate thermal insulation and provide protection of the channels from damage – protective covers are used for this.

To ensure protection from external factors of thermal insulation of ventilation ducts and technological equipment, it is recommended to use casings that are made of galvanized sheet, stainless steel or aluminum. Covers for ventilation ducts of rectangular cross-section are made up to 3000 mm long. The thickness of the metal is from 0.45 mm to 1.2 mm. The shell allows you to protect communications from the effects of moisture, ultraviolet radiation, prevents the formation of condensation on the insulated surface, mechanical damage and other environmental factors, gives the systems a complete and aesthetic appearance. Shells are used for various types of insulation sheet materials (mineral wool plates, NPE); tubes or removable casings with a “spike-groove” sealing system (thermal insulation mineral wool cylinders, PPS, PU foam, foamed polyethylene); rolled (all types of mineral wool, unstitched polyethylene); liquid insulation (PU foam, ceramic compositions).

Advantages of protective covers:

● They are particularly durable, withstand long-term operational loads.

● Resistance to various chemicals.

● Easy installation: the ability to quickly replace the elements in case of damage.

● The possibility of reuse.

● Effective protection of communications and insulation from the effects of moisture, ultraviolet radiation, prevents the formation of condensation on the insulated surface, mechanical damage and other environmental factors.

The casing for ventilation ducts is made according to the customer’s technical specifications with the necessary overlaps, plugs for thermal insulation, taking into account the direction when installing the structure (prevents moisture from entering the structure), with ready-made mounting holes that facilitate its installation, in accordance with the requirements of GOST. For fixing the thermal insulation material, at the request of the customer, we additionally complete with cotter pins, for fixing thermal insulation materials.

THERMAL INSULATION STANDARDS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Name of the indicator | Normative value of density marking | ||||||||

80 | 100 | 120 | 150 | 200 | |||||

Density, kg/m³ | 67 • 84 | 85 • 102 | 103 • 123 | 124 • 150 | 151 • 200 | ||||

Thermal conductivity, W / mK,

no more at a temperature of | 10°С | 0,035 | 0,036 | 0,036 | 0,038 | 0,04 | |||

(25 ± 5)°С | 0,036 | 0,038 | 0,038 | 0,042 | 0,048 | ||||

(125 ± 5)°С | 0,047 | 0,047 | 0,048 | 0,051 | 0,053 | ||||

(300 ± 5)°С | 0,085 | 0,085 | 0,086 | 0,088 | 0,090 | ||||

Mass fraction of organic substances (%) not more than | 5 | 5 | 5 | 5 | 5 | ||||

Humidity (% by weight) no more than | 1 | 1 | 1 | 1 | 1 | ||||

Tensile strength (Mpa) not less than | 0,01 | 0,015 | 0,015 | 0,02 | 0,025 | ||||

Compressive strength at 10% deformation

of the thermal insulation layer (Mpa) is not less than | 0,01 | 0,01 | 0,015 | 0,03 | 0,05 | ||||

HVAC protective shells are characterized by effective performance characteristics, withstand high operating temperatures, effectively retain heat, are strong and durable. It is easy to cut and other processing, easy to install.

Mineral wool thermal insulation HVAC is not affected by chemical elements (alkalis, acids), as well as ultra-violet and electro-magnetic radiation, are easy to install and very technologically advanced in processing (they are easily cut even with household tools), are durable and retain their working properties throughout the entire service life.

The vandal-proof HVAC shell made of thin-sheet steel is resistant to mechanical loads, anti-corrosion, low thermal conductivity, moisture resistance, non-combustibility.

Due to the fact that the galvanized HVAC casing consists of several segments, so it is easy to install it in the shortest possible time. In addition, such a collapsible design provides free access to the ventilation line and allows you to quickly carry out repair work. Installation does not require special skills and abilities, since basalt insulation is easily cut into the desired segments. Galvanized steel has remarkable performance characteristics – it is resistant to mechanical loads, is not subject to corrosion, allows you to quickly get free access to ventilation, carry out work related to its operation.

CHARACTERISTICS: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height: up to 1200 mm. | ||||||||

| Width: up to 1200 mm. | ||||||||

| Length: up to 3000 mm. | ||||||||

| Metal type and thickness: Zn 0,50/0,55/0,80/1,00 mm; Al 0.80/1.00 mm; St 0.50/1.00 mm. | ||||||||

| Angle α: According to the Customer’s technical specification. | ||||||||

| Mounting holes: Ø3. 2 mm (According to the Customer’s technical specification). | ||||||||

| Marking of insulation: 80; 100; 120; 150; 200. | ||||||||

| The thickness of the thermal insulation: from 20 to 200 mm. | ||||||||

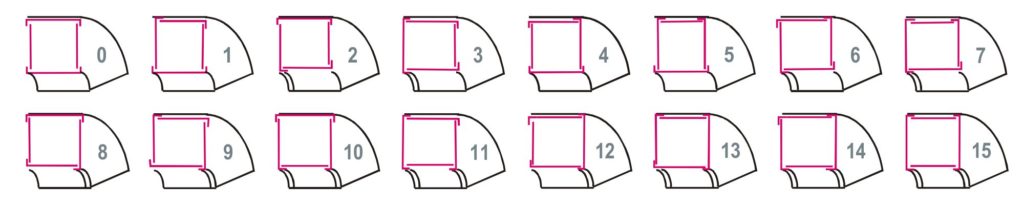

| Mounting direction: ► Two-sided or Directional. | ||||||||

Installation of HVAC does not require the use of special devices and is carried out by attaching the finished structure directly to the ventilation line, followed by fixing with self-tapping screws or exhaust rivets.

HVAC protective shells for industrial and civil applications are used for the protection and thermal insulation of heating, ventilation and air conditioning lines.

The wide application and popularity of the finished structure are due to the universal properties of the thermal insulation and protective shell used in it, quick and easy installation. Mineral wool is an economical and eco-friendly material, resistant to aggressive environments, acids and oils, has a high fire resistance.

The protective shell of the QDC made of galvanized steel has been tested by time and the Russian climate, which is characterized by sharp temperature changes and high humidity. The design has successfully proven itself in the thermal insulation of open ventilation lines used in various construction and administrative complexes, industrial enterprises, medical and educational institutions, food industries, sports facilities and high-rise buildings.

It is used to protect ventilation systems. They are attached to the surface by covering the outer surface of the ventilation line.

The HVAC protective shell will save heat and extend the service life of the ventilation system, as well as it serves as a reliable protection against mechanical damage.

Types of fasteners of the shell of the structure:

| Self-tapping screw DIN 7504 M(N) |  | Exhaust rivet |

The design of the HVAC for ventilation systems is supplied complete with products that facilitate its installation, in accordance with the requirements of GOST:

● Special cutting tool;

● metal tape for insulation of joints from moisture and water;

● hardware kit (self-tapping screw DIN 7504 M (N); exhaust rivet);

The HVAC design for ventilation systems, designed for effective waterproofing and thermal insulation of open areas of ventilation lines, is supplied in reinforced cardboard boxes. It is worth considering that such packaging is not intended for storing products in the open air!

Online form for technical specialists:

*If you have any questions or difficulties filling out the form, you can contact our engineer at any time.

Our engineer will be happy to help you make all the necessary calculations and choose the right types of products for your tasks in accordance with all the requirements and technical specifications.

| ● ● ● IT IS IMPORTANT TO KNOW! ● ● ● |

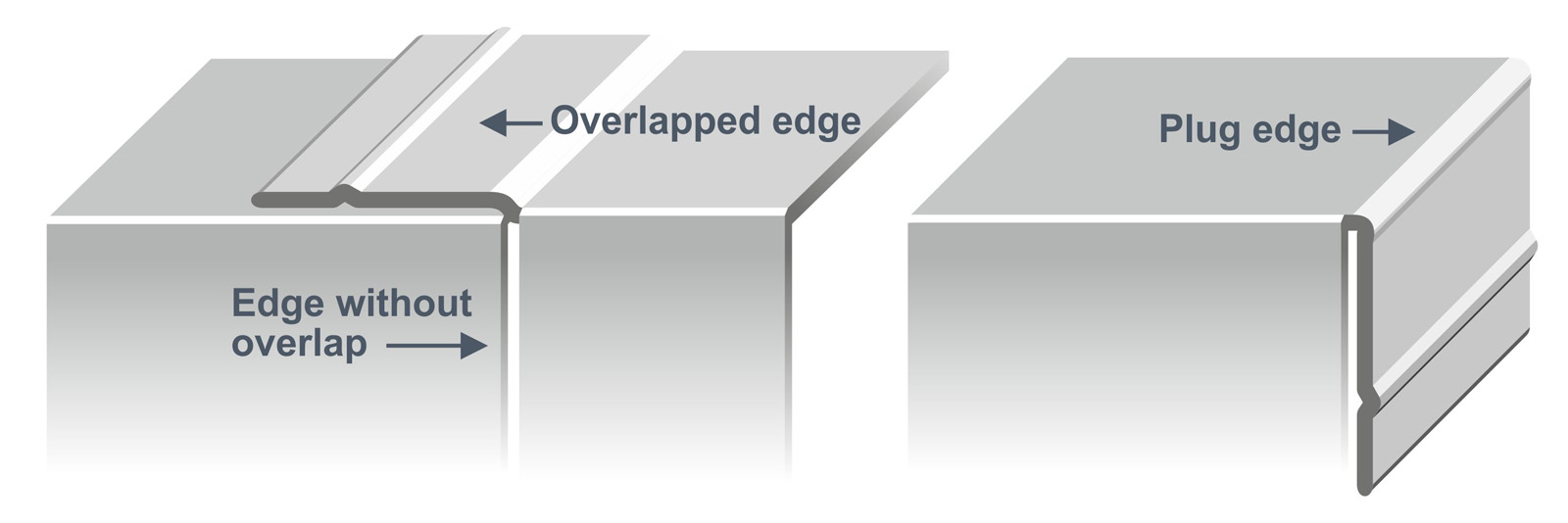

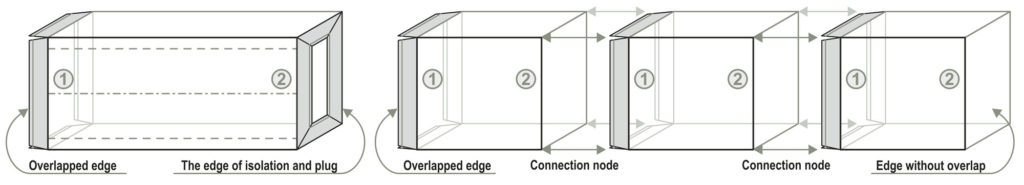

| Types of directions of connections of the protective shell: |

|

| Example of section connections during assembly and installation: |

|

| The standard overlap of the shell edge for a nodal connection with another section of the HVAC is 35 mm (+15 mm zig). For the plug of the insulation edge, the overlap of the shell edge is indicated in accordance with the thickness of the thermal insulation. |

| Recommendations: |

Protective metal casings-shells can be used in the arrangement of thermal insulation of horizontal ventilation lines without the use of supporting structures. It is recommended to strengthen and seal the joints of the sections of each product, to protect the internal space of the structures from moisture and dust. A necessary condition for installation-the work should be carried out in dry weather to avoid precipitation in the form of moisture or condensate on the surface of the insulation. |