“STANDARD” OR “PREMIUM”?

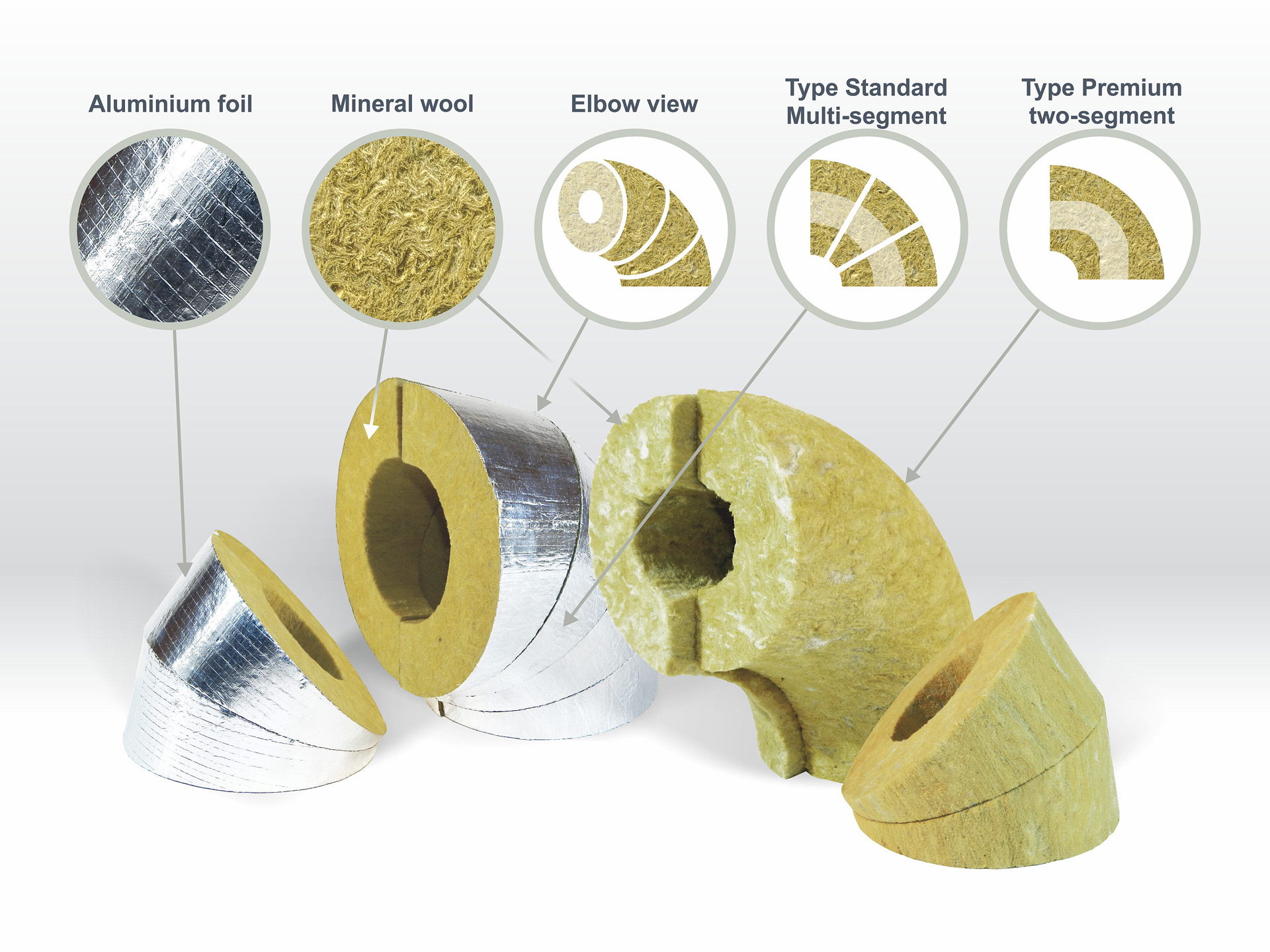

The company’s product range PIPEWOOL includes 2 versions of the tap: Type III “Standard” and Type I “Premium”.

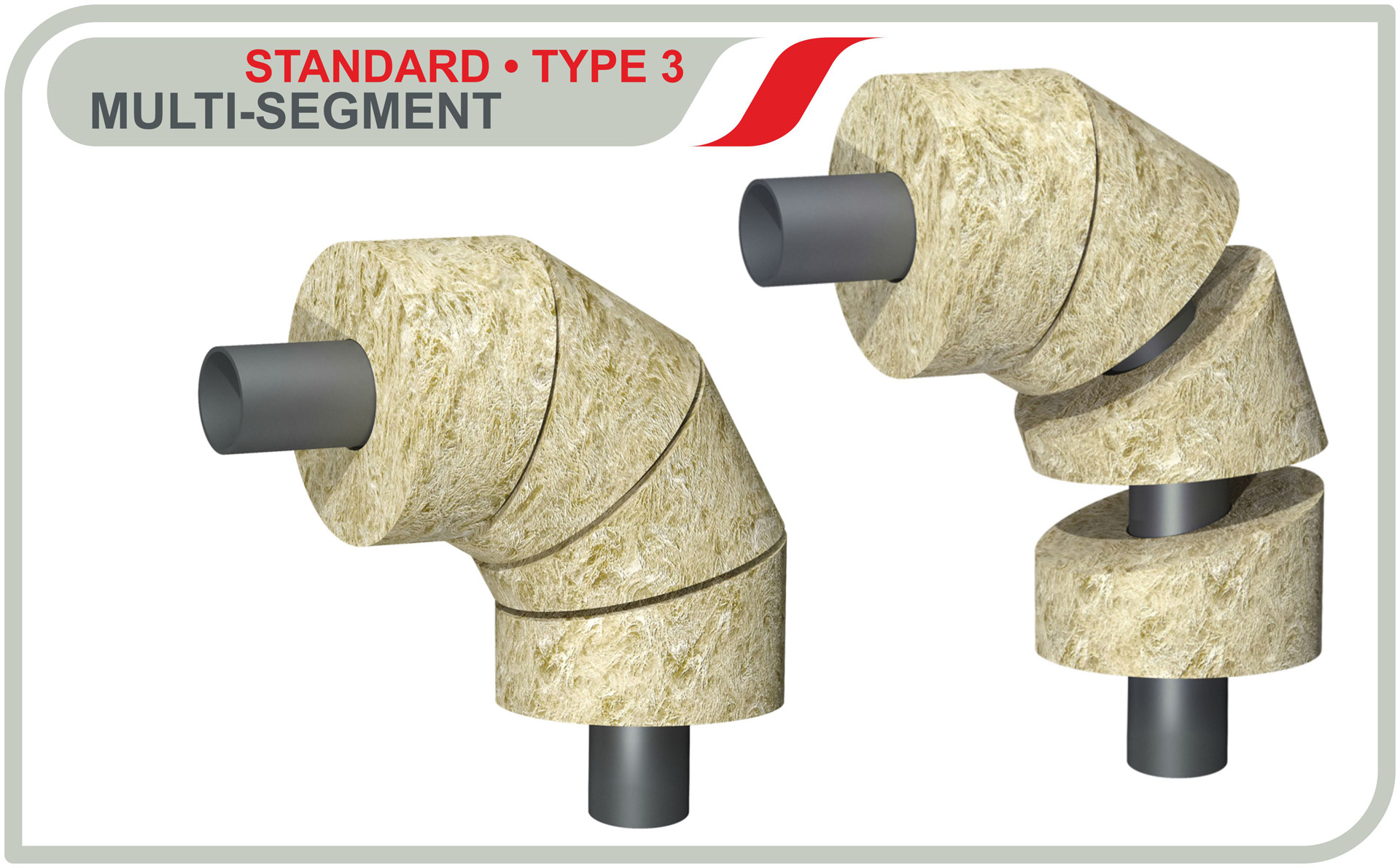

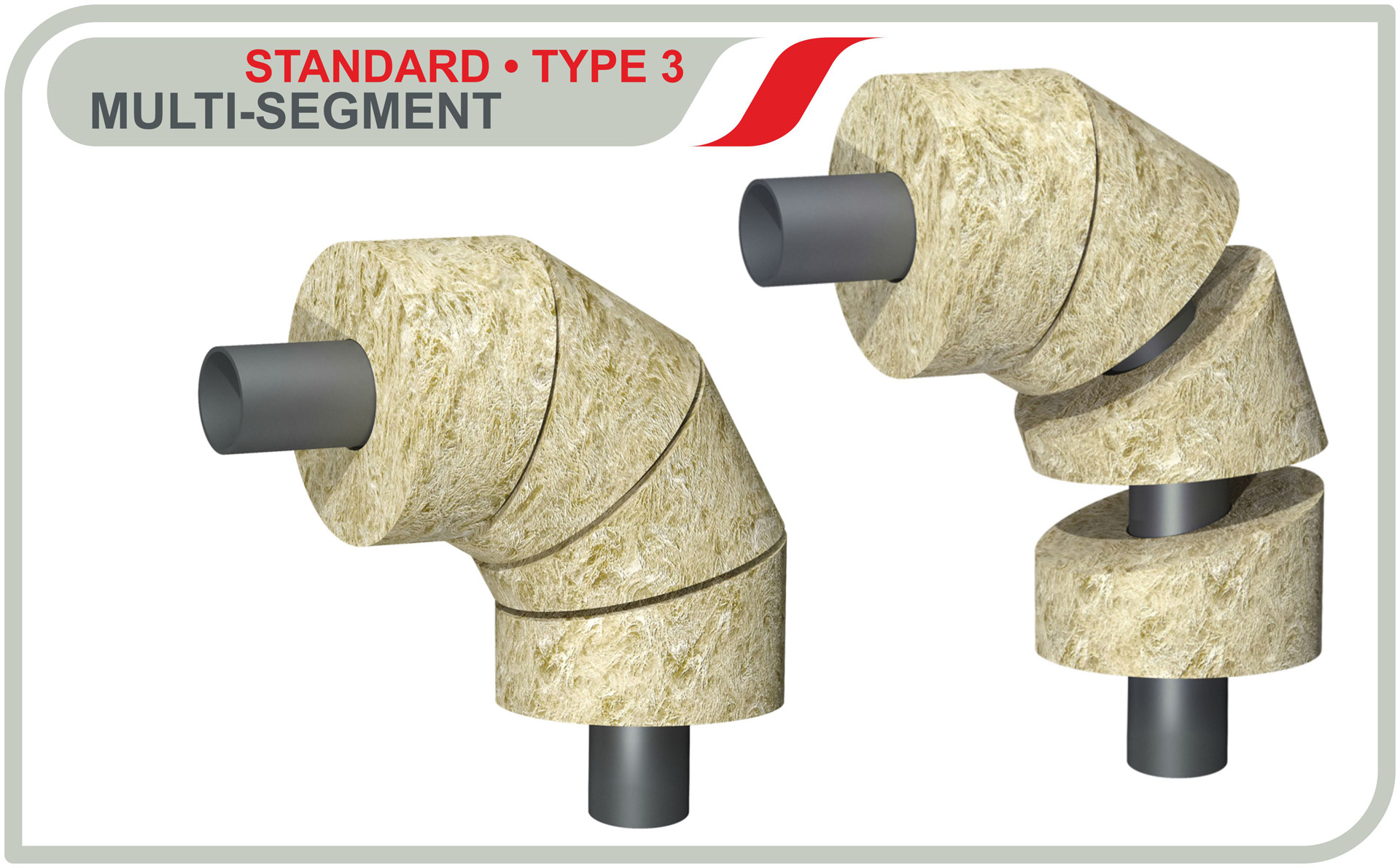

Type III “Standard” • this is the usual multi-segment taps of mineral wool based on basalt rocks, produced at some production sites in Russia and the CIS.

Type I “Premium” • a new version on the Russian market. The tap consists of only two segments, which reduces the installation time by 2-3 times, saves employees ‘efforts and saves customers’ money.

The price difference between these options is compensated by the speed with which the tap is assembled, because you will not need to assemble it from many parts.

Thermal insulation taps made of mineral wool are used for insulation of supply and main pipelines in the gas, oil, chemical industry and at industrial enterprises of water and heat supply. Thanks to their special shape, they simplify the process of thermal insulation of pipes in places where the main line turns or turns at different angles.

At the request of the customer, the bends can be covered with galvanized sheet or aluminum foil. Such a metal layer protects the insulation from external influences, wetting and shrinkage, makes it possible to use taps in areas with high humidity.

PIPEWOOL taps can be supplied with the following accessories:

● Tool for strapping products;

● aluminum adhesive tape for waterproofing joints;

● Metal bandages with buckles for fixing bends.

All products are packed in a reinforced cardboard box, which allows them to be transported over long distances without losing their properties.

In order to simplify the isolation of the steeply curved pipeline nodes, the branches from the mineral wool are cut into several parts. The number of segments, as well as the angle of their cut, are calculated in advance by our specialists. Call the contact phone number to make the necessary clarifications!