Design of thin-sheet steel shells: Standard according to TECHNICAL CONDITIONS 4937-002-61278130-2016

Attributes: Ready to install.

Length: 500, 625, 1000, 1200, 1250 mm.

Thickness: Zn 0.5-1.2 mm, Al 0.50-0.80 mm, SSt (stainless steel) 0.50 mm.

Diameter: From 60 mm in increments of 10 mm, 6 holes for rivets or self-tapping screws with a diameter of 3.2 mm.

Mounting direction: Double-sided, end and longitudinal zig.

All over the world, the most common coatings that protect open pipeline networks from external influences are galvanized protective casings.

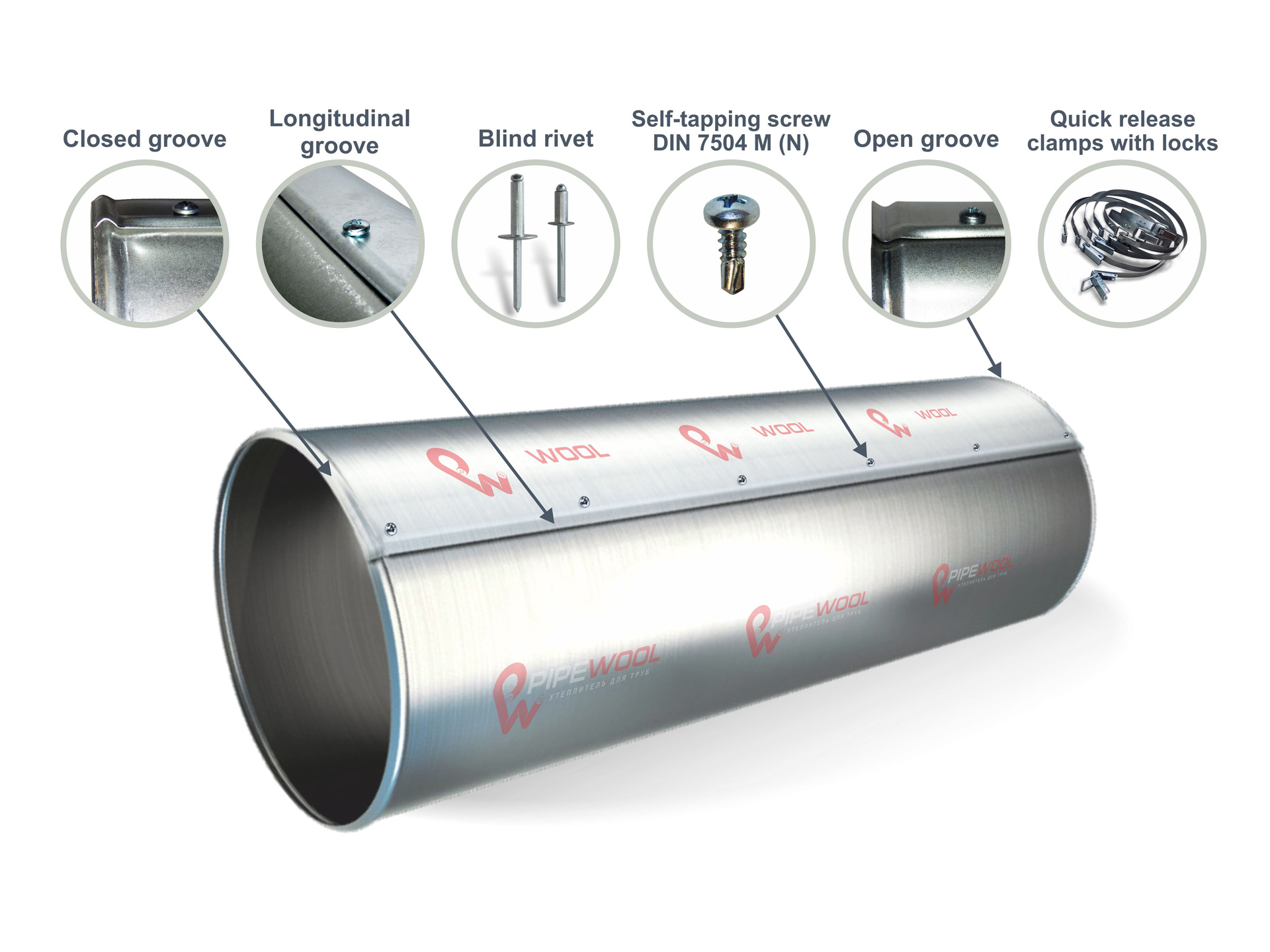

The casing is a product in the form of a cylinder with knurled drainage stiffeners. This is a multifunctional collapsible protective structure that is mounted on the pipeline.

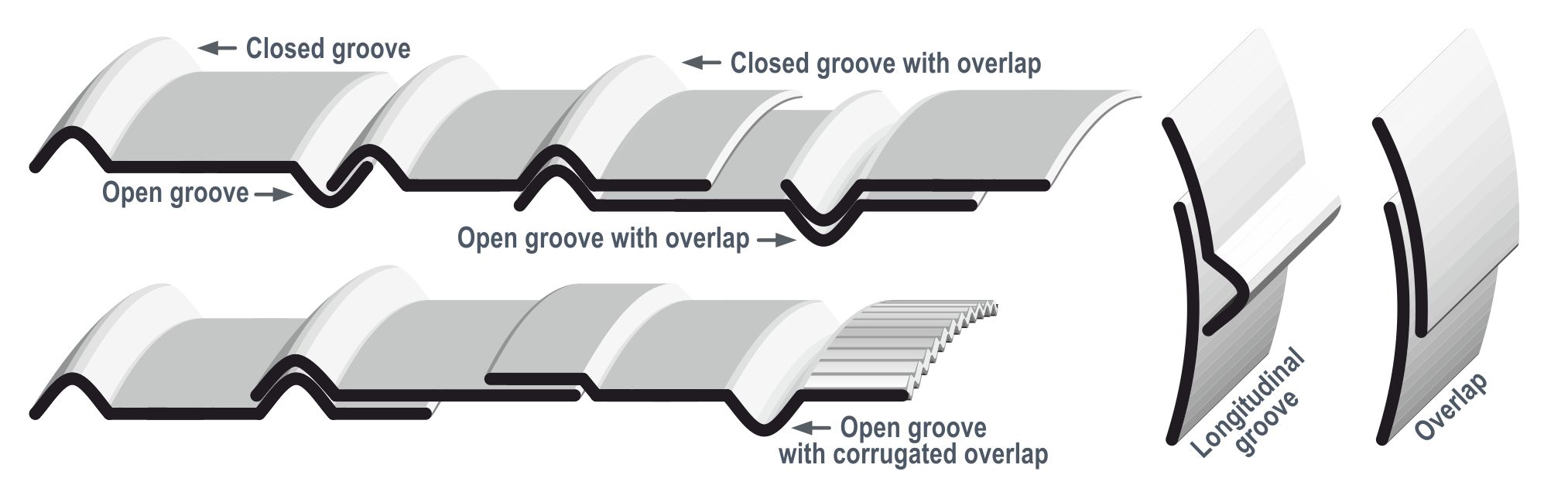

The design of the PIPEWOOL casing provides for longitudinal and end overlays.

On the pipe for quick access to the heat-insulating material, the casing is fixed with buckles and a bandage tape.

The protective shell of the pipelines made of galvanized steel has been tested by time and the Russian climate, which is characterized by sharp temperature changes and high humidity. The design has successfully proven itself in the thermal insulation of cold and hot water supply pipelines used in various construction and administrative complexes, industrial enterprises, medical and educational institutions, food production, sports facilities and high-rise buildings. In any case, the galvanized shell for pipes and heat-insulating cylinders will save heat and extend the service life of the pipeline.

It is used to protect the thermal insulation layer on pipeline systems made of mineral wool cylinders and mats, as well as polyurethane foam shells, penoplex segments. They are attached to the finished thermal insulation structure by covering the outer surface of the insulation.

Steel casings-shells perform the functions of protecting the insulation material from mechanical damage and additionally securing the thermal insulation material to the pipeline.

The galvanized casing for pipelines is supplied complete with products that facilitate its installation, in accordance with the requirements of GOST:

● Special cutting tool;

● aluminum or propylene banding tape for attaching the product to an insulated surface;

● metal adhesive tape to insulate joints from moisture and water;

● Fasteners made of anti-corrosion metal or composite plastic for fixing bandages.

The heat-insulating galvanized shell for pipes, designed for effective waterproofing and thermal insulation of open sections of pipeline lines, is supplied in reinforced cardboard boxes. It is worth considering that such packaging is not intended for storing products in the open air!

Protective metal casings-shells can be used in the arrangement of thermal insulation of horizontal pipelines without the use of supporting structures. But it is recommended to strengthen each product with two metal or polypropylene bandages, fastened with buckles.

A necessary condition for the installation – the work must be carried out in dry weather to avoid precipitation in the form of moisture or condensation on the surface of the insulation.