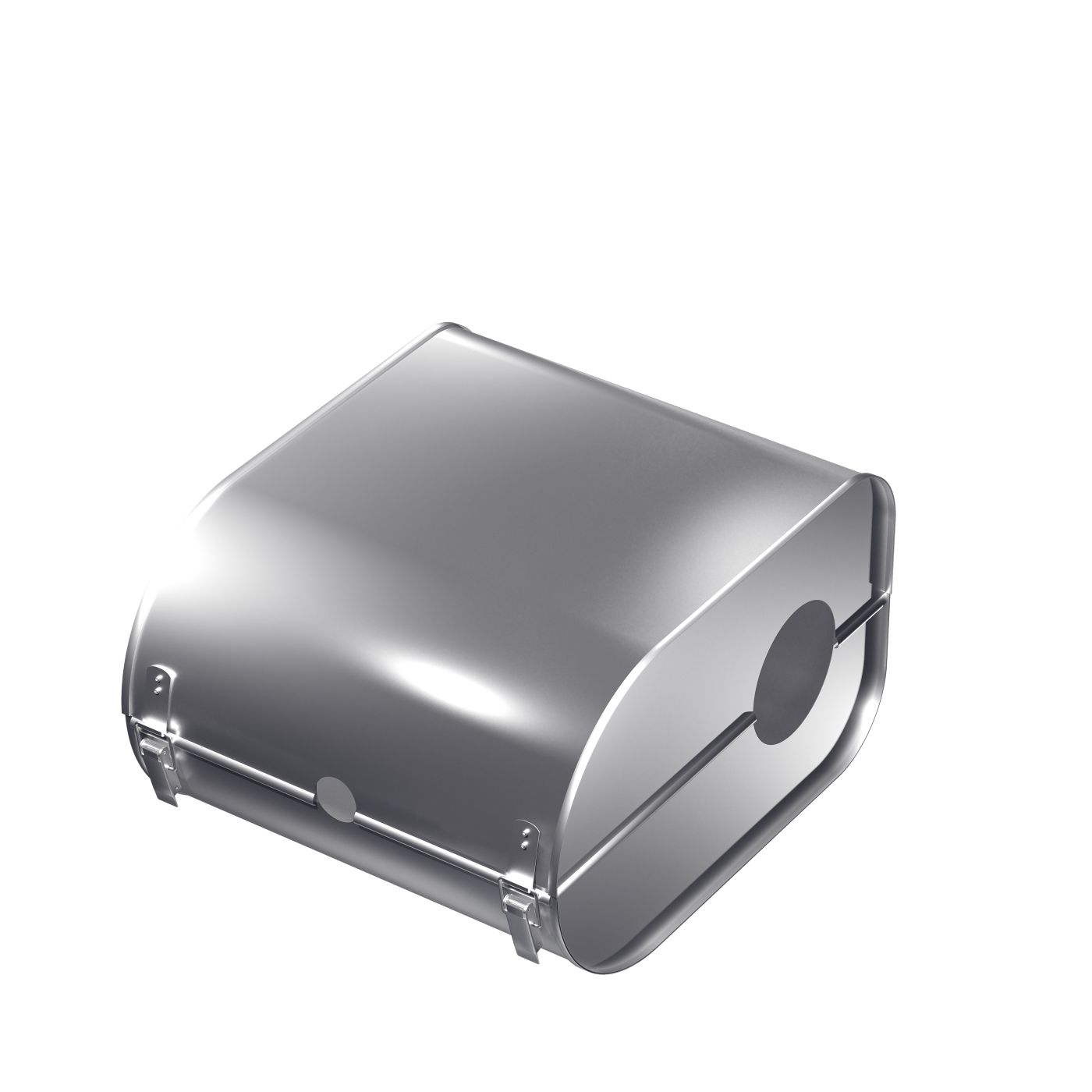

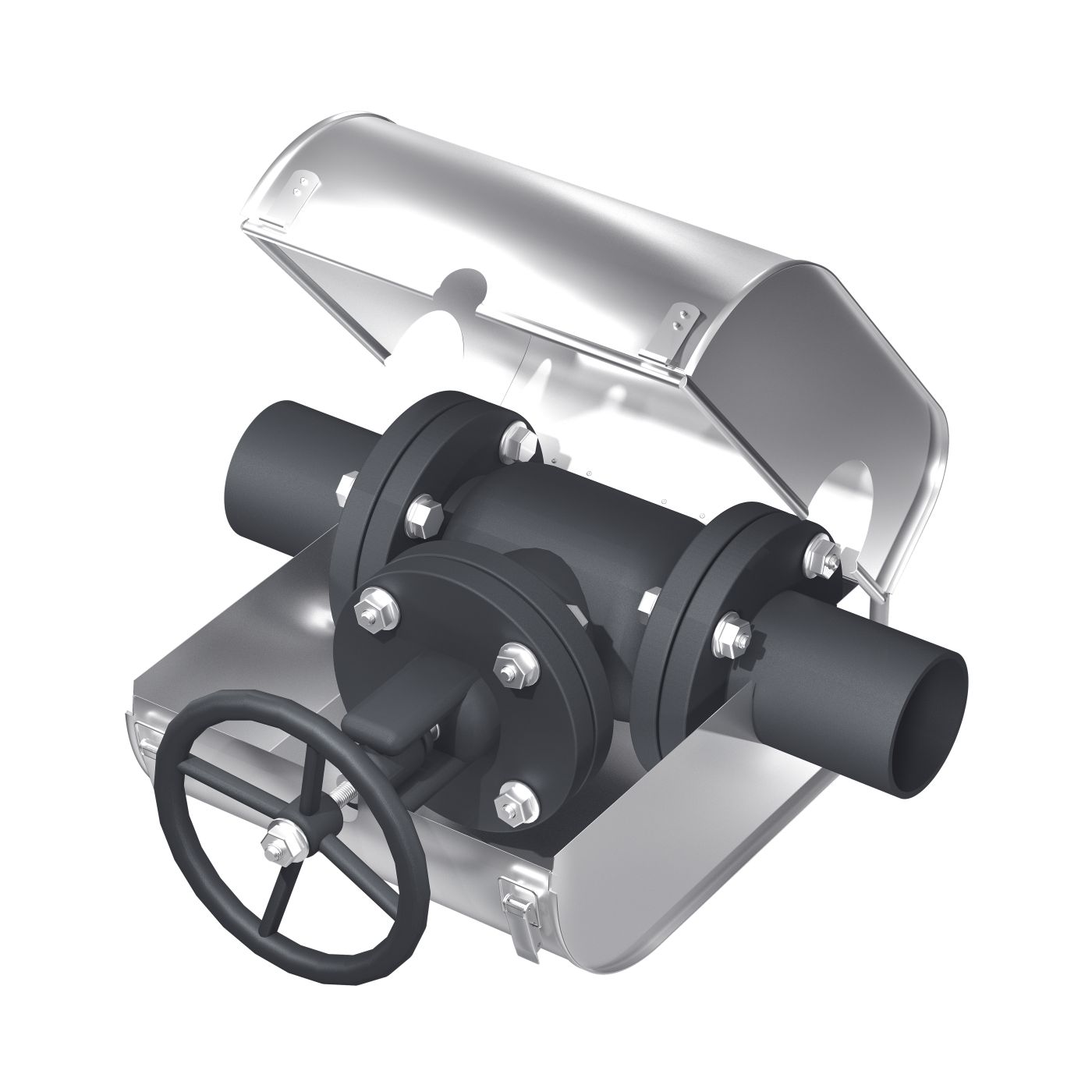

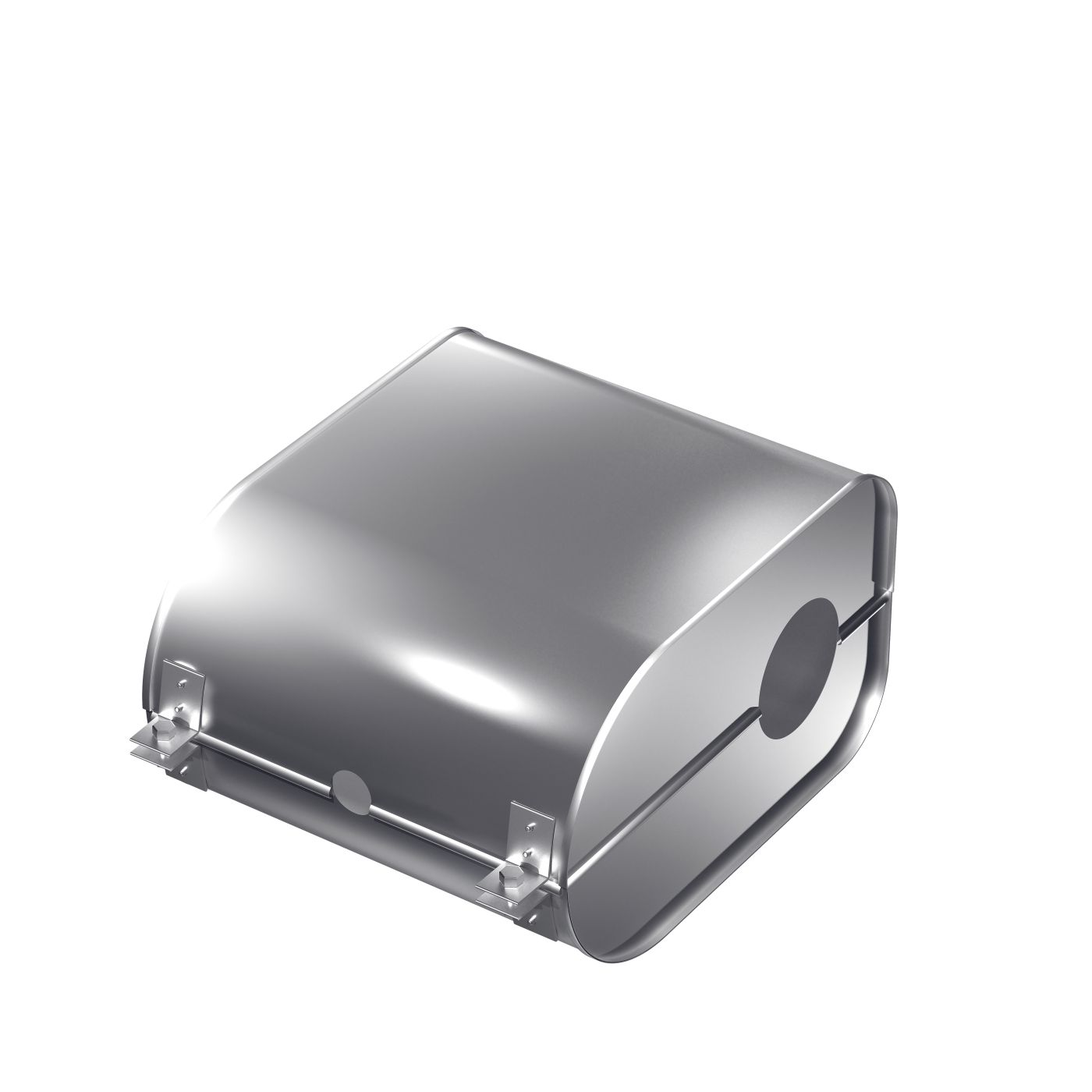

The design of the protective casing for flanged connections of pipelines, valves and pipe fittings has successfully proven itself in the operation of cold and hot water supply, during the transportation of hazardous substances or liquids with high temperature, under high pressure, used in various construction and administrative complexes, industrial enterprises, oil and chemical industry enterprises, medical and educational institutions, food production, sports facilities and high-rise buildings.

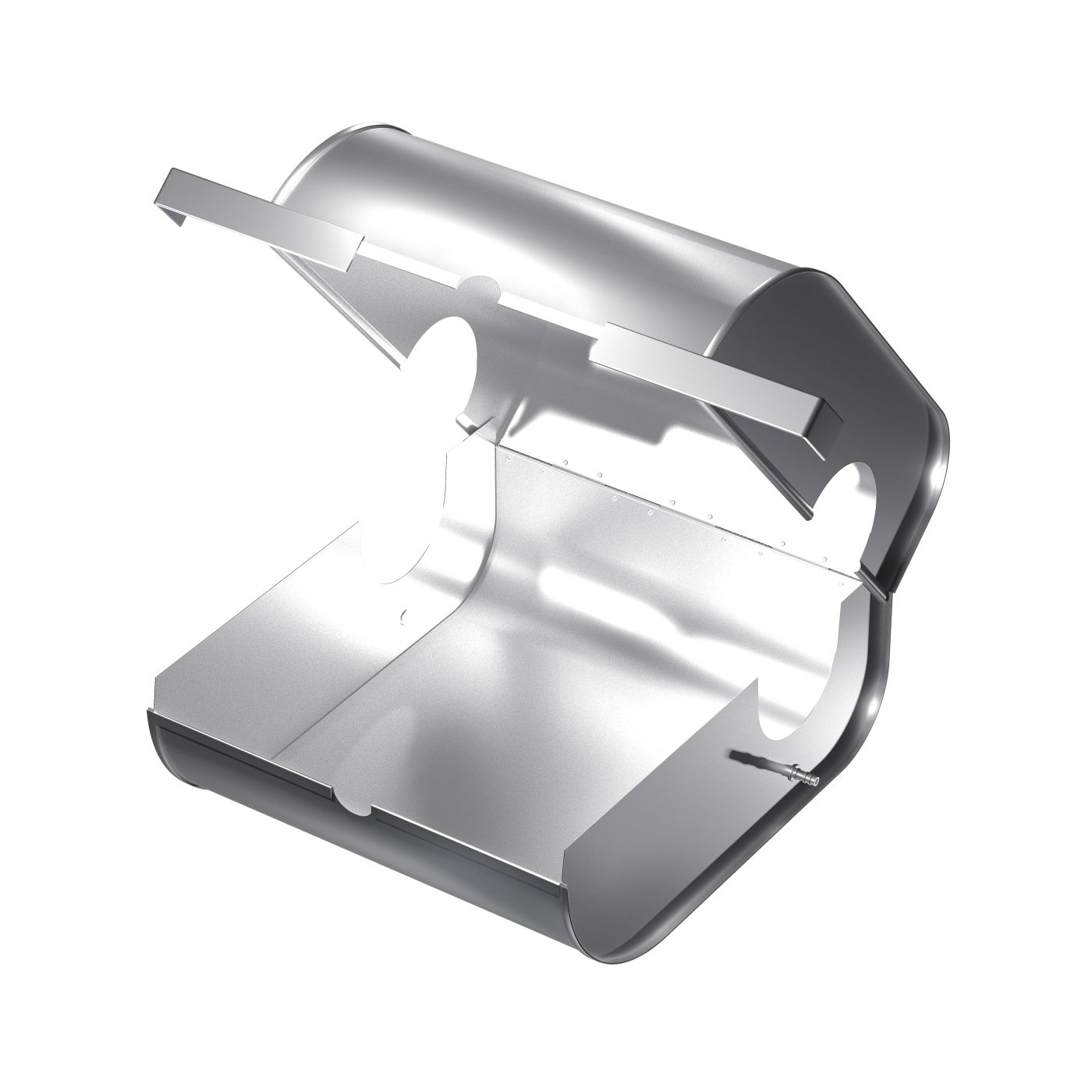

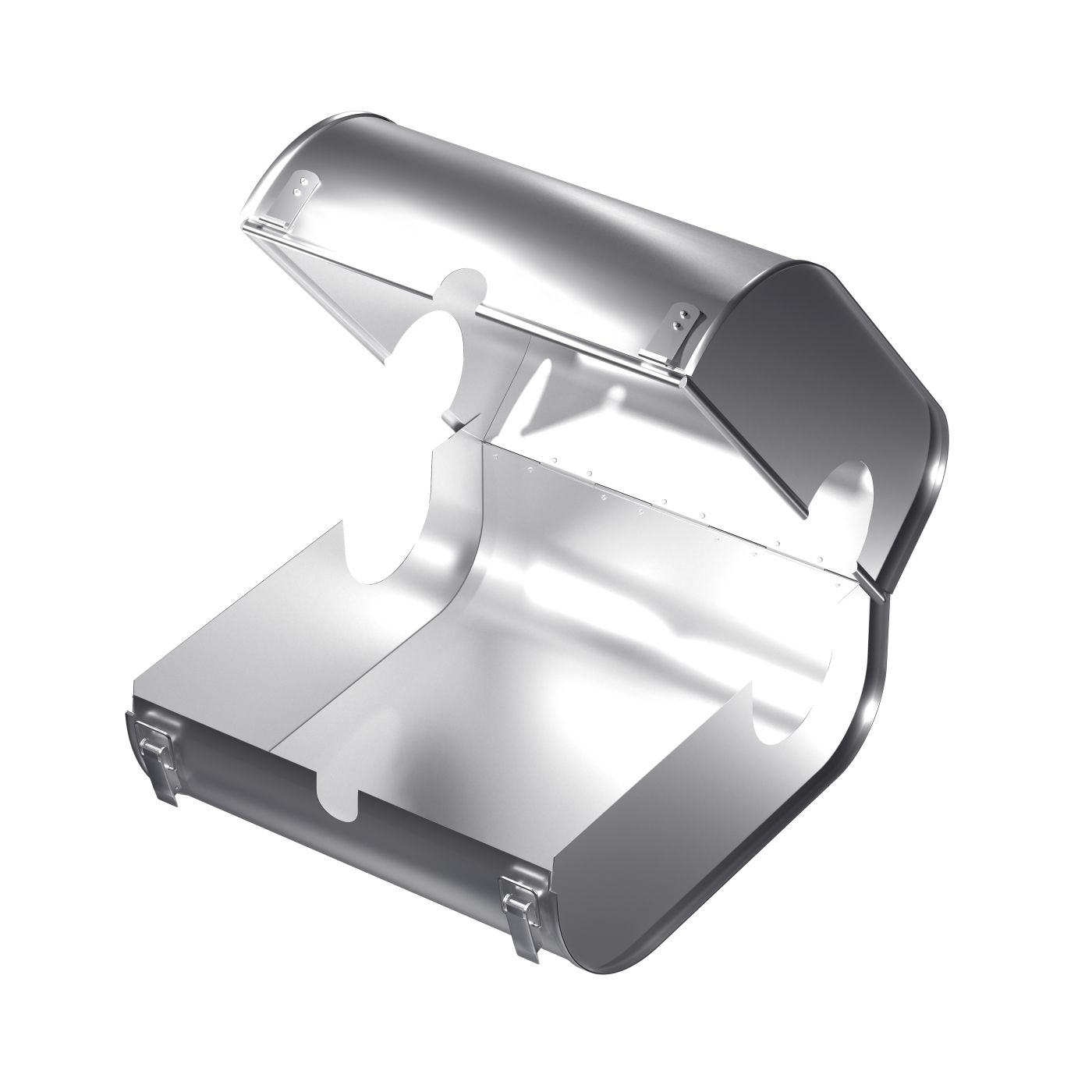

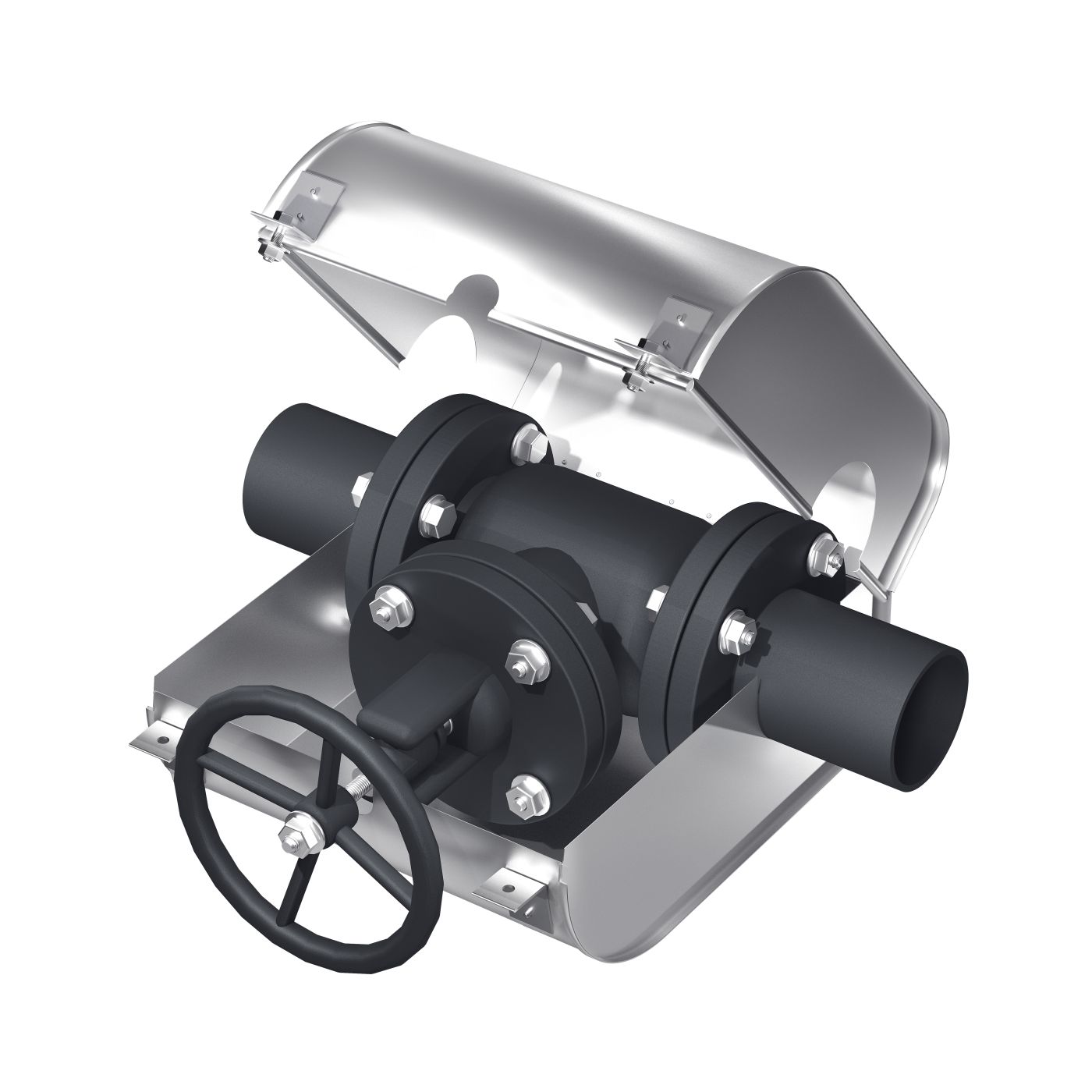

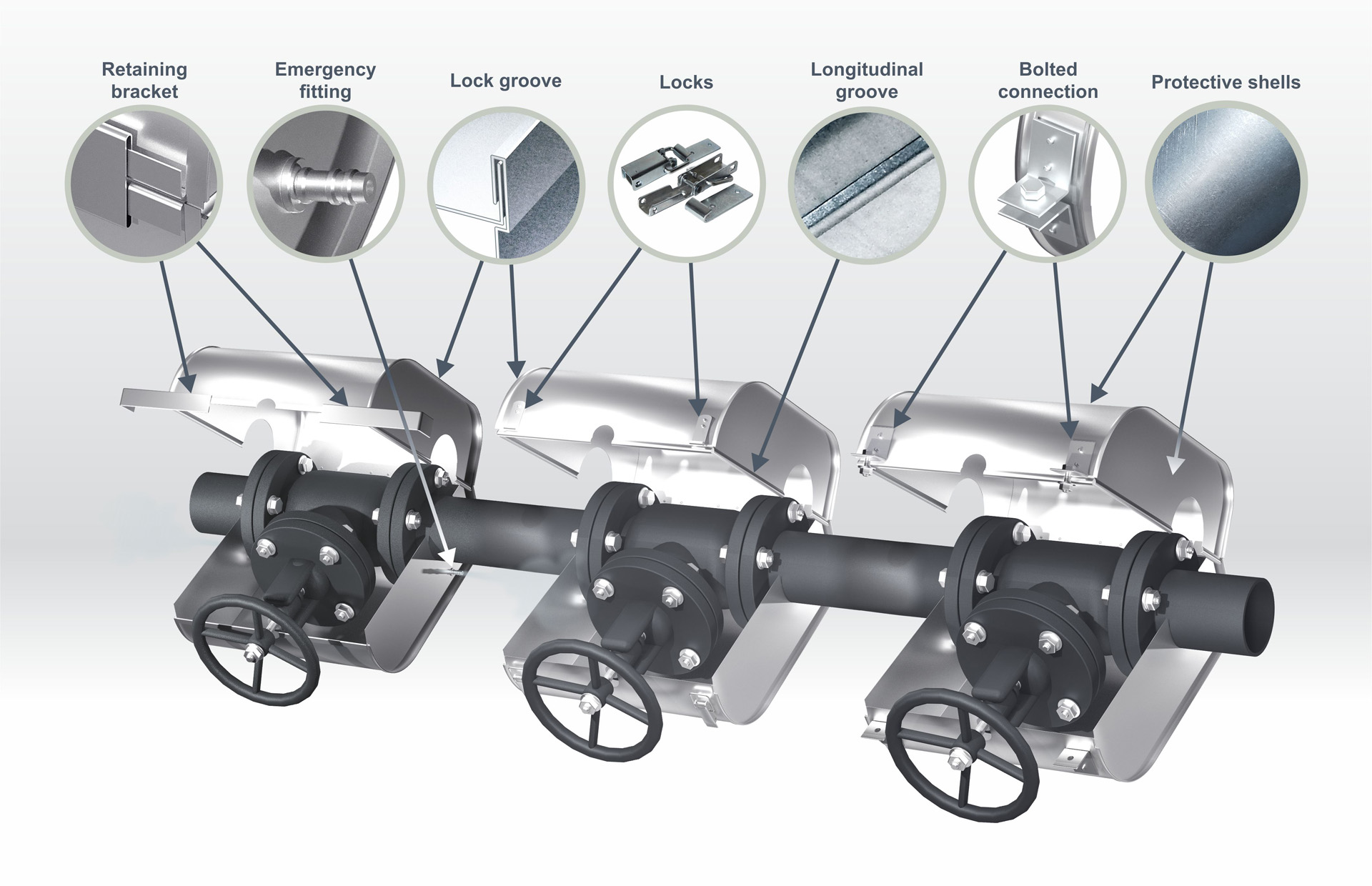

It is used to protect the maintenance personnel during the emergency maintenance of the pipeline “at the sections of their connections”. They are attached to the flanged connections of the pipeline, valves and pipeline fittings, by “covering them externally with” quick-release connections.

It is installed on flanged connections to protect against spilling of dangerous working media in case of violation of the tightness of the gasket materials, the impact of corrosion of the connected surfaces.

Purpose of protective covers:

● The product belongs to the field of auxiliary protective devices for connecting pipeline components, such as flanged connections and shut-off valves.

● The product is designed to protect personnel and surrounding equipment from splashing of high-temperature liquids and gases pumped under pressure, including aggressive and toxic, taking into account their dangerous effects on humans, emissions associated with the depressurization of flange connections or valves.

All the casings used must provide reliable protection of personnel, the possibility of repeated use, convenience and ease of installation.

● They are installed on the flanges of pipelines that pump liquid reagents and chemical media that do not cause any impact on the material of the protective casing.

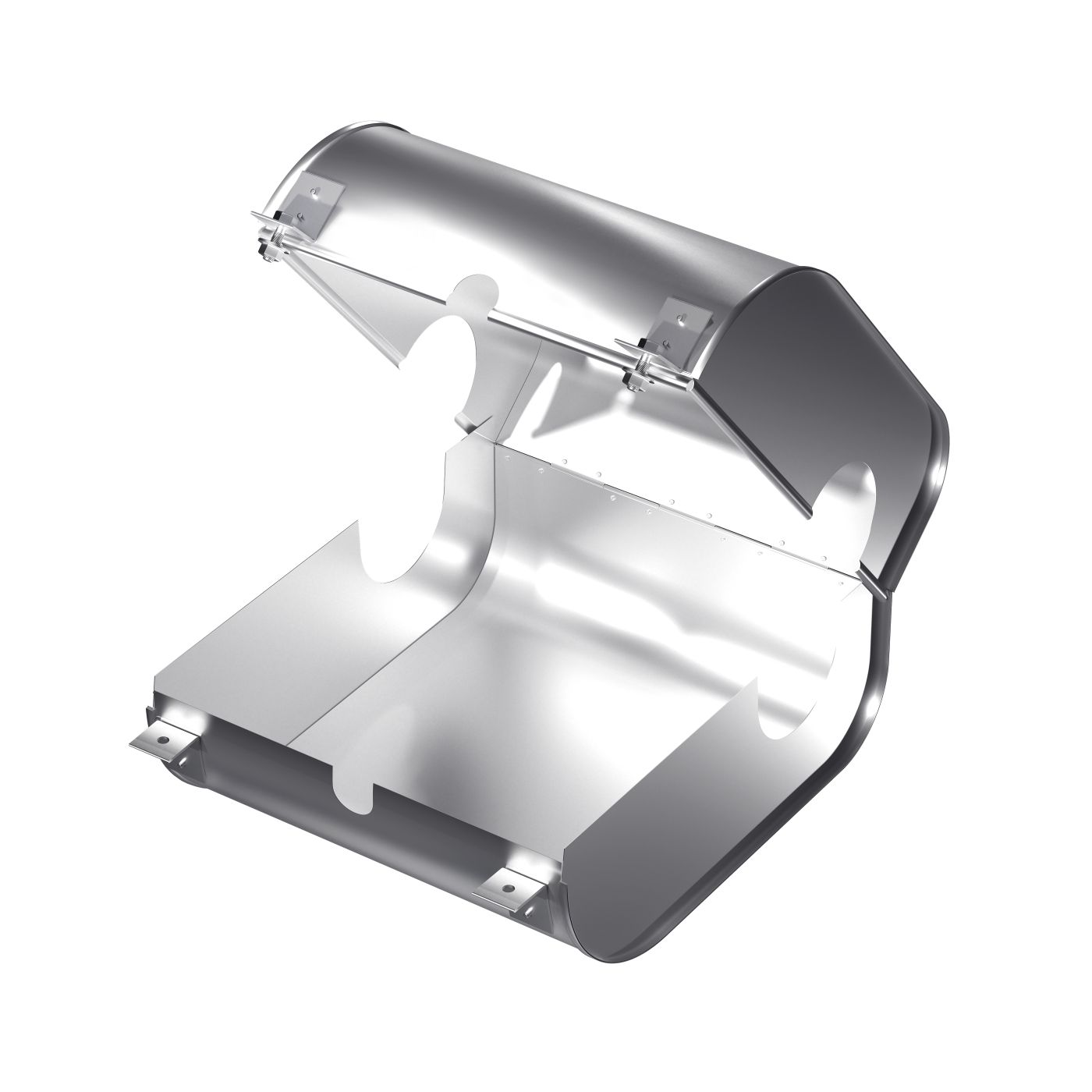

In accordance with the wishes or necessary conditions of the Customer, dictated by the requirements of the project used, the design of the protective casing can be made with additional emergency equipment in the form of drainage holes, an emergency hose or a fitting, as well as additionally painted in the desired color.

For a reserve margin of safety and preservation of the integrity of the protective structure, in case of emergency maintenance, it becomes necessary to have drainage holes to reduce the excess load on the protective casing.

Drainage holes are made on the structure from those sides that are directed from the access side to it. The pressure of liquids in an aggressive state, as well as their vapors, is drained through the holes. They prevent the splashing of liquids and make their direction predictable.

*Drainage holes are not allowed on the accessible side of the structure for maintenance!

To set the predicted direction of the jet of vapors and splashing liquids, fittings are used, which, unlike simple holes, cope with this task more efficiently, which significantly increases the safety of using the protective casing when servicing them in case of emergency situations. The fittings are installed in the holes on the structure from those sides that are directed from the access side to it.

*It is not allowed to install fittings on the accessible side of the structure for maintenance However, in order to be able to divert the direction of the jet vector, the fittings must be located so that access to them is not difficult!

There are situations when there is a need to divert even the predicted direction of the jet. To set a certain direction of the vector of the discharge of the jet of vapors and splashing liquids, an emergency reinforced high-pressure hose is put on the fitting.