Tanks are among the most complex structures for most industries. Thanks to precise computer calculation and manufacturing on modern CNC machines, this task becomes easy to solve and ensures high quality. We offer ready-made solutions for heat-insulating protective structures of any complexity.

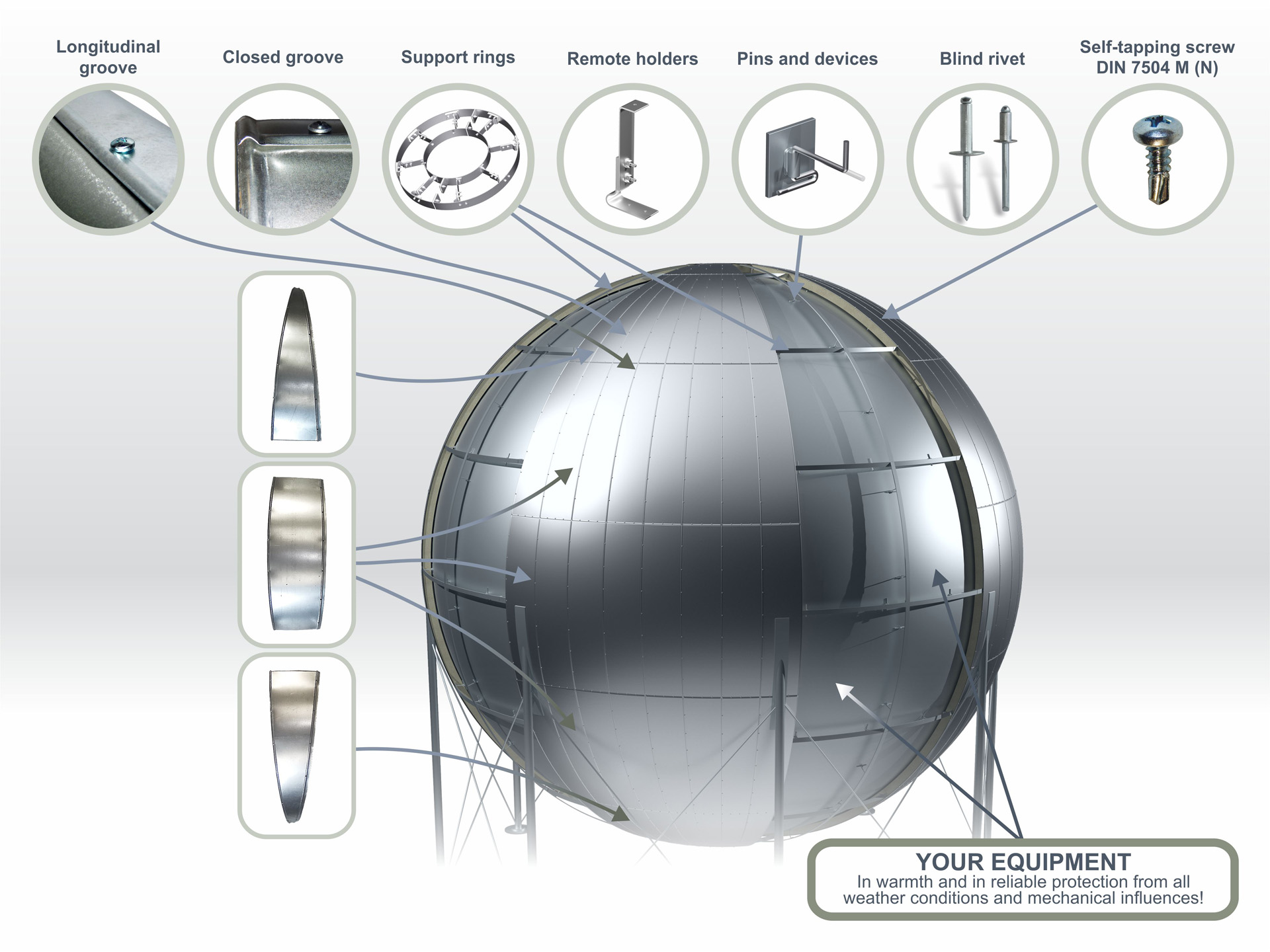

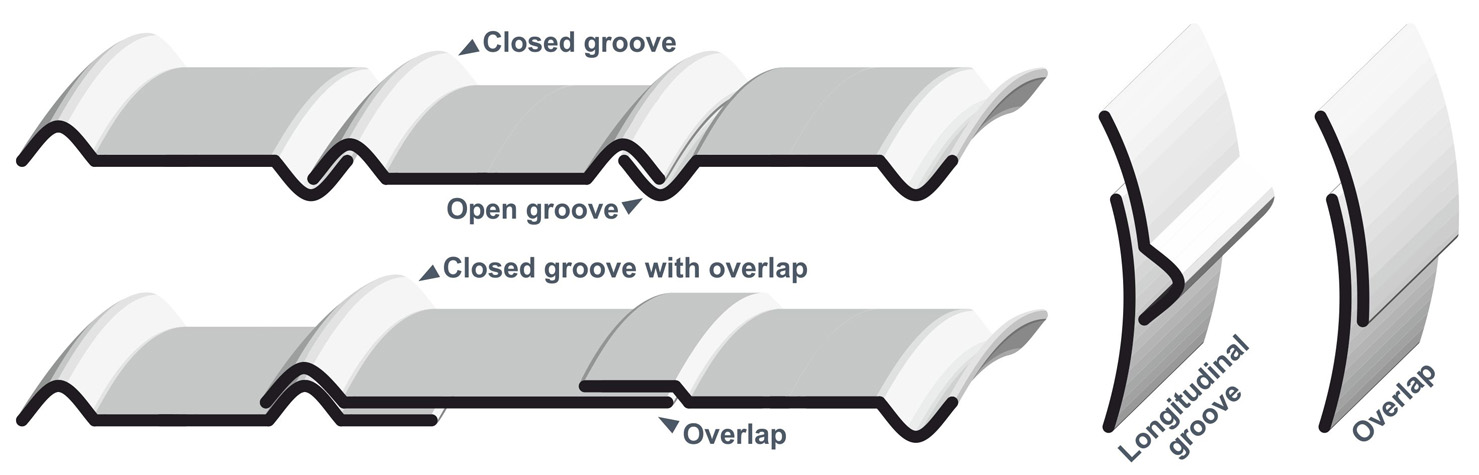

● Protective shell for the sphere Pipewool S Zn/Al/St – a modern solution for protecting thermal insulation and pipeline networks from external influences. It is a protective coating made of thin-sheet steel. Special stiffeners, longitudinal and end overlays, technological locks allow you to prevent moisture from entering the casing.

● The sphere is additionally equipped with the corresponding additional products. For example: plugs, support rings, remote holders or pins for fixing thermal insulation.

*For additional staffing, please refer to another order form. And also, you can ask for help from our manager or engineer.