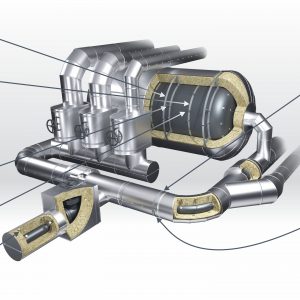

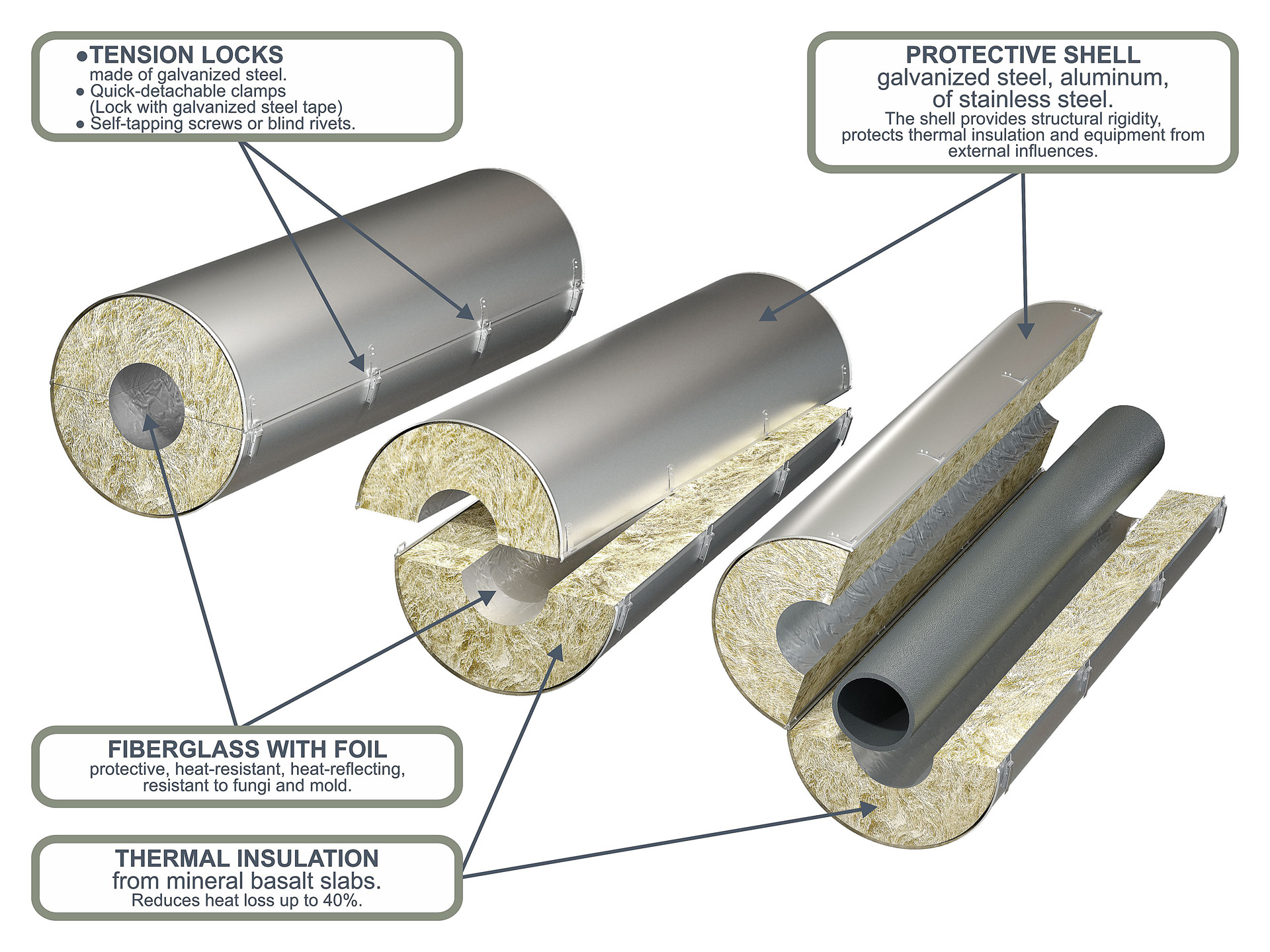

Heat-insulating cylinders in a galvanized shell are hollow heat-insulating structures made of mineral wool and galvanized shell. They have a special strength and durability, due to both the uniformity and elasticity of the basalt fiber without secondary crystalline inclusions, and special additives.

The main features of mineral wool cylinders PIPEWOOL Zn.

Allow during operation:

● Significantly reduce the heat loss of the entire structure;

● Increase the service life of metal pipes;

● Protect the pipeline from mechanical damage, moisture and high temperat

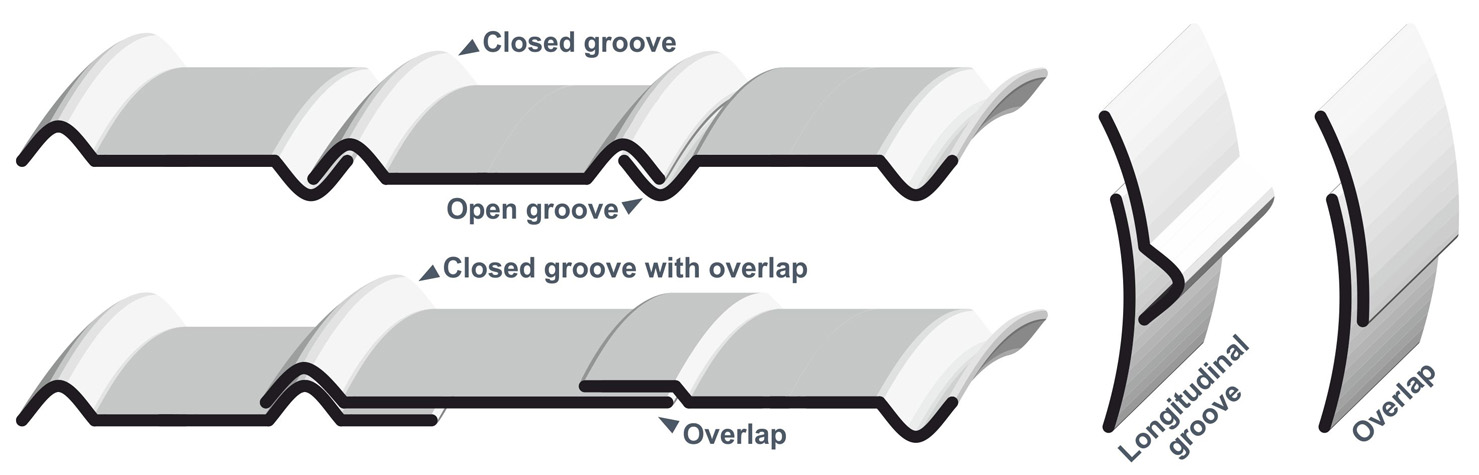

Mineral wool galvanized cylinders PIPEWOOL perfectly protect the pipeline from moisture and further rusting, thanks to the drainage zigzags and butt overlays of the shells provided during the installation of the cylinders.

Galvanized cylinders are made of stone wool, the raw material for the production of which is mountain basalt rocks. Due to the fact that the melting point of the fibers exceeds 1000 degrees, the cylinders can be used in wide temperature ranges.

The protective galvanized shell prevents the cylinders from mechanical damage and climatic influences, performing protective functions.

In the design of the cylinder, drainage ridges, end and longitudinal butt overlays of shells are provided to prevent moisture ingress.

Depending on the diameter of the structure, the cylinders with a protective coating of zinc are produced in one-piece or segment-by-segment assembly.

* The products are delivered assembled (laminated) or separated (cylinder-shell).